Oil mist is generated during cutting operations in factories. While measuring oil mist concentration is not mandatory, it is advisable to do so considering its impact on the human body and environment. This article will introduce the allowable oil mist concentration, measurement methods, and the expected impact of oil mist dispersion. We will also explain how to deal with oil mist, so please take a look.

INDEX

Oil mist concentration measurement obligations and allowable concentrations

The permissible concentration of 3 mg/m 3 proposed by the Japan Society for Occupational Health serves as a guideline.

It has been pointed out that inhaling oil mist not only increases the risk of lung damage but also increases the risk of cancer. To protect the health of workers who work near equipment that uses water-insoluble cutting oils, there is an increasing need to properly measure and manage concentrations at each workplace. The Japan Society for Occupational Health has announced that the exposure limit is 3 mg/ m³, but there is no obligation to measure concentrations.

What is oil mist?

Oil mist is small particles of oil suspended in the air. For example, in metal cutting and processing sites, when machines with cutting oil or lubricating oil on them operate at high speed, the oil breaks down into fine particles and becomes suspended in the air as oil mist.

Oil mist is also generated when lubricating oil gets mixed in when compressed air is produced, or when oil evaporates due to temperature rises in the workplace. Cutting oil and lubricating oil are necessary to prevent tool deterioration and to produce beautiful finished products, but we must also consider their impact on the human body and environment.

Why measure oil mist concentration?

Although measuring oil mist concentration is not mandatory, it is recommended that oil mist concentration be managed and measured in workplaces where operations that generate oil mist such as metal processing, are carried out. If oil mist concentration continues to exceed the allowable standard, various undesirable effects will occur. Let's take a look at the main effects.

- Effects on the human body and health

- Impact on the work environment

- Impact on machinery and equipment

Effects on the human body and health

Oil mist floating in the air can cause pain and irritation if it adheres to the skin or gets into the eyes. In some cases, workers may unknowingly inhale oil mist while working, which can lead to respiratory illnesses.

Additionally, the distinctive smell oil mist can cause discomfort and headaches.

Impact on the work environment

If oil mist concentration is not properly controlled, oil mist will remain on the ceiling, walls, floors, etc. of the factory, making it easier for dust and dirt to accumulate, which could make the entire factory unsanitary.

In addition, if there is a large amount of oil mist attached, oil droplets may fall from the ceiling and the floor may become slippery, making it easier for workers to fall or slip, increasing the likelihood of accidents occurring in the workplace.

Impact on machinery and equipment

Oil is necessary for the smooth operation of machinery and equipment, but oil mist floating in the air can have a negative effect on machinery and equipment.

For example, if the concentration of oil mist in the air remains high for a long period of time, oil mist may get into panel and air conditioning equipment, causing malfunctions and corrosion. Regular maintenance can prevent malfunctions, but it is not only time-consuming, but also costly and time-consuming.

Oil mist concentration measurement method

There is no obligation to measure oil mist concentration, and there are no clear rules or standards for the method of concentration measurement. When measuring concentration, measurement standards must be determined for each workplace.

There are no clear standards for measuring oil mist concentration, such as those set out in the Industrial safety and Health Act. As with general work environment measurements, more accurate measurements can be obtained by measuring periodically at fixed points using the same methods.

For reference, we will list some points to consider when deciding on a measurement method for general work environment measurements.

- Determining unit work location

- Determining the measurement points

- Deciding on the measurement date and time period

- Deciding on the equipment to be used for measurement

Typical measurement methods and measuring instruments

Oil mist concentration can be measured using a variety of methods and measuring devices depending on the characteristics of the measurement environment and the purpose of the measurement. However, it is important to note that it is difficult to evaluate just the oil mist oil mist, as the measurement also measures dust particles floating in the air.

Below we introduce some typical measurement methods and the equipment used for them.

- Filter weighing method

- Piezo balance type

- Light scattering type

- Microscopy

Oil mist concentration is measured using a dedicated measuring device. However, since it is difficult to measure the concentration of oil mist alone, it is common to use a method that measures the amount of dust suspended in the air. Here are some typical measurement methods.

- Filter weighing method

-

Filter The weighing method is a method of taking suspended dust on filter paper and measuring its weight with a balance to calculate the concentration in the atmosphere. Without a special machine, it is possible to measure the concentration of dust, including oil mist.

Typical measuring equipment: Low-volume air sampler, sampling pump + collection filter

- Piezo balance type

-

The piezo balance method uses static electricity to collect dust particles suspended in the air and measure their weight on a balance. Because it can remove large particles before measurement, it is more accurate than filter weighing method. Another advantage of the piezo balance method is that it can measure concentration in a short time.

Representative measuring instrument: Piezo balance dust meter

- Light scattering type

-

The light scattering method uses a laser to shine a laser beam on the collected dust and measure the amount and flow of oil mist based on the intensity of the light. Because it has a simple structure and is relatively inexpensive, it is also used in household air purifiers.

Representative measuring instruments: light scattering digital dust meter, particle counter

- Microscopy

-

This method involves collecting airborne dust particles, creating a sample, and then directly observing it under a microscope to analyze the shape and size of the particles.It is possible to simultaneously measure the size, shape, and surface condition of particles, and is characterized by the fact that it can obtain an overwhelming amount of information compared to other measurement methods.

Typical measuring equipment: Low-volume air sampler, sampling pump + collection filter

In addition to measuring the concentration, measures against oil mist are necessary

If proper oil mist countermeasures are not implemented, the concentration may continue to exceed the standard level, which may have adverse effects on the human body, the working environment, and machinery, and may even cause damage.

To maintain a good environment, it is necessary to measure oil mist in addition to measuring its concentration. One measure that should be considered is the introduction of mist collector.

Create a comfortable environment with mist collectors!

High-performance mist collector can effectively capture oil mist of various sizes, ensuring a comfortable working environment and protecting the health of people working on-site.

What is mist collector?

Mist collector is a device that keeps the air and environment in a factory clean by sucking in oil mist and separating and removing it from the air.

mist collector are divided into several types depending on their internal structure. It is important to select the appropriate type and installation method according to the machine and environment in which mist collector will be installed.

Main types of mist collector

Mist collector are divided into filter type, disc type, cyclone type (filter-less type), and electrostatic precipitator type depending on their internal structure. Please see below for the features and mechanisms of each type.

| Collection method | Features |

|---|---|

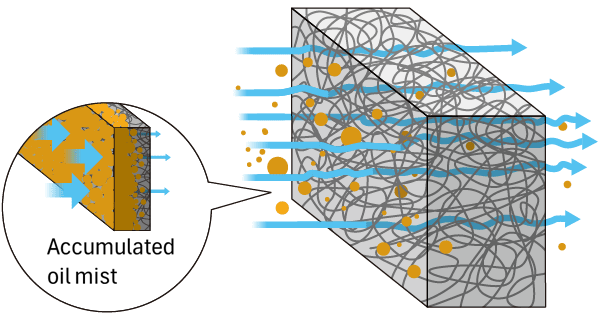

Filter expression

|

This system captures particles through a physical filter. It has a simple structure and can be managed without specialized knowledge. filter needs to be replaced periodically. |

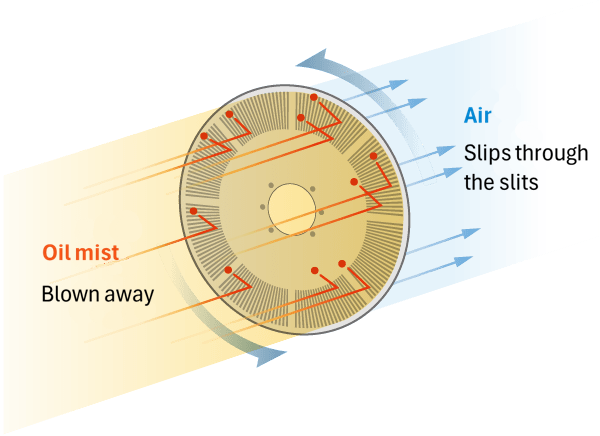

Disc type

|

The particles are collected by colliding with a disk that rotates at high speed. As there is no filter, there is an advantage that industrial disposal is not generated when filter replacement. |

Cyclone type (filter-less type)

|

It separates particles using centrifugal force. It is said that the particle size that can be collected by a general cyclone is only a few micrometers or more, and the collection efficiency is inferior to that of electric and disc types. However, the advantage is that there are fewer replacement parts. |

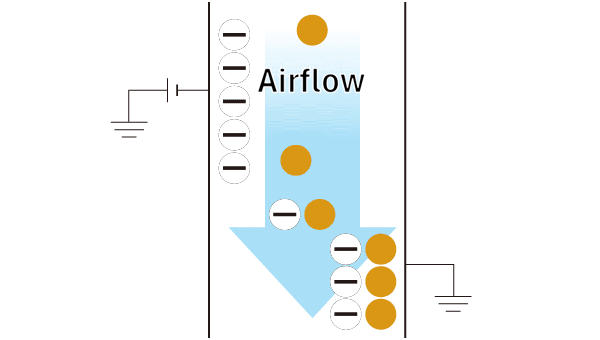

Electrostatic precipitator

|

It uses electrostatic force to adsorb and capture oil, and can capture even fine particles. However, the initial investment is high, and care must be taken when handling the high-voltage equipment. |

Apiste 's mist collector use a disk-type design that is easy performance maintain. If you are interested in the GME-S-Pro/eco series mist collector, which not only offer easy performance but also excellent collection performance and energy efficiency, please see below.

Measure oil mist concentration and take countermeasures

Oil mist not only pollutes the workplace environment, but can also have adverse effects on humans and machinery. To create a safe and comfortable workplace, it is necessary to properly measure oil mist concentrations and take measures.

If you have any concerns about oil mist countermeasures or the introduction of mist collector, please feel free to contact us using the form below.