Mist collector are devices that suck up and remove oil mist generated by factory production activities, and play an important role in improving the working environment. This article provides detailed information on the types of mist collector and how to install them efficiently. We also introduce actual installation examples and recommended mist collector, so please take a look.

INDEX

What is mist collector?

Mist collector is a device that removes harmful particulate matter, especially oil mist, generated in factories. mist collector separate the air and oil mist, and then suck in and collect oil mist floating in the air.

Particulate matter such as oil mist, dust, and fumes that are generated in the air during production activities in factories can contaminate the work environment and cause health problems for employees. Therefore, it is important to remove these substances by installing general ventilation or local exhaust ventilation systems according to the properties of the substances.

Mist collector play an essential role in sucking in oil mist, which is classified as particulate matter among harmful substances, and separating it from the air.

If you are looking for mist collector click hereThe effects of oil mist and the benefits of installing mist collector

Oil mist has various effects on the work environment. Here we will explain in detail the effects of oil mist and the benefits of introducing mist collector.

Preventing effects on the human body

Oil mist can cause eye and skin diseases if it comes into direct contact with the eyes or skin. Inhaling oil mist can also have adverse physical effects, such as headaches and discomfort. mist collector are devices that help reduce these health risks and improve the working environment. Furthermore, installing mist collector improves visibility within the factory, leading to increased productivity.

Preventing impact on machinery and equipment

If oil mist adheres to electronic devices, it can cause short circuits. It also often causes corrosion of metal and plastic parts. Introducing mist collector can extend the life of machinery and equipment and help reduce maintenance costs.

Preventing environment impact

Oil spills in factories affect safety by causing poor visibility and making floors and walls slippery. Oil smoke also poses the risk of fire and explosion. mist collector can maintain environment within factories by removing oil smoke and oil mist.

Learn more about oil smokeTypes of mist collector and how to choose them

Mist collector are essential equipment for dealing with oil mist in factories. Understanding the characteristics of each collection method and selecting the one that best suits your factory's conditions is the key to creating a safety and comfortable working environment.

| Collection method | Features |

|---|---|

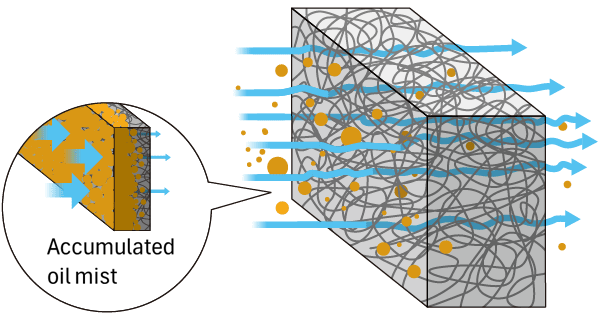

Filter expression

|

This system captures particles through a physical filter. It has a simple structure and can be managed without specialized knowledge. filter needs to be replaced periodically. |

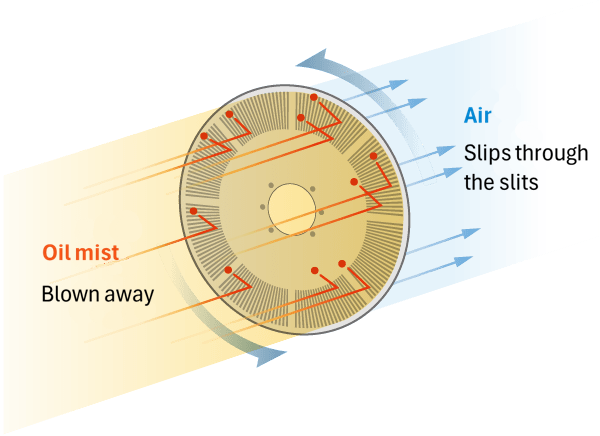

Disc type

|

The particles are collected by colliding with a disk that rotates at high speed. As there is no filter, there is an advantage that industrial disposal is not generated when filter replacement. |

Cyclone type (filter-less type)

|

It separates particles using centrifugal force. It is said that the particle size that can be collected by a general cyclone is only a few micrometers or more, and the collection efficiency is inferior to that of electric and disc types. However, the advantage is that there are fewer replacement parts. |

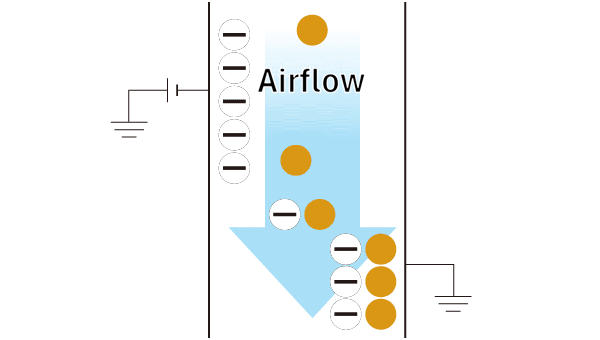

Electrostatic precipitator

|

It uses electrostatic force to adsorb and capture oil, and can capture even fine particles. However, the initial investment is high, and care must be taken when handling the high-voltage equipment. |

How to install mist collector

There are several installation methods for mist collector. Selecting the installation method that best suits the working environment of your factory is important to maximize performance of mist collector.

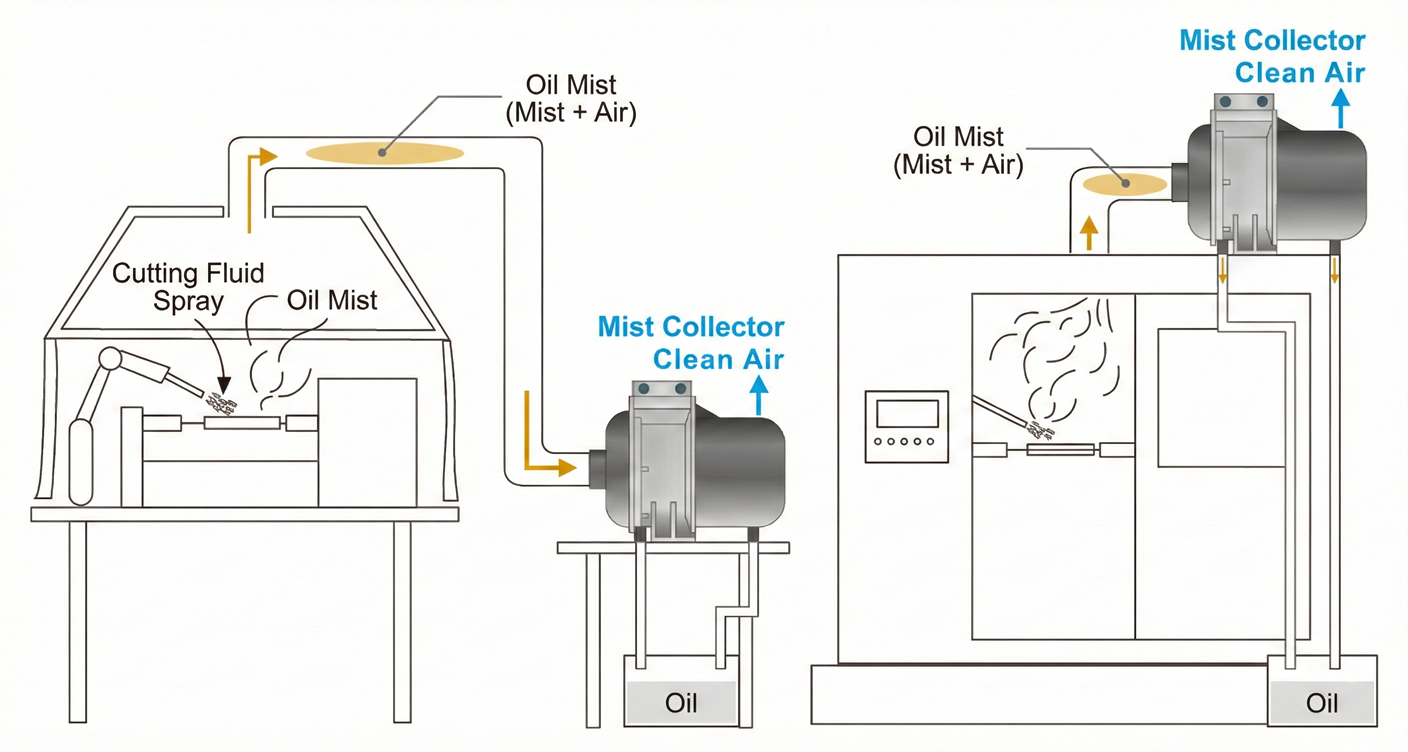

[When the processing area is sealed] Direct intake method

The "direct intake method" is an installation method used for machine tools whose machining areas are sealed. With the direct intake method, it is installed on machines that perform precision work in closed spaces, such as CNC lathes and machining centers. It can efficiently suck in oil mist generated from the machining area, maintaining the cleanliness inside the machine tool.

[When the processing area is open] Local intake method

The "local intake system" is often used for machine tools with open processing areas. With the local intake system, a hood is installed near the source of dust or oil mist, and air is sucked in locally. The local intake system is an installation method suitable for machines with exposed processing areas, such as press machines and general-purpose lathes.

[Other] Wide-area intake system

The wide-area intake system is a method of drawing in air from the entire work space and collecting oil mist in the air. It is sometimes installed in combination with the "direct intake system" or "local intake system" that address specific work areas. Because it purifies air over a wide area, it helps maintain the air quality throughout the factory. In practice, there are cases where air conditioners with mist collector functions are installed, or small mist collector are installed in various locations.

Apiste 's mist collector

Apiste 's high-performance mist collector, the GME-S-Pro/eco series, is mist collector that pursues ease of maintenance, collection performance, and energy saving.

In factories where mist collector are required, the conditions that generate oil mist vary from site to site, including differences in cutting oil, processing methods, workpieces, etc. In addition, the maintenance systems at each site and performance required of mist collector also vary.

To meet the various needs of each site, Apiste offers two mist collectors in its lineup: the GME-S-Pro series, a professional and eco-friendly model that maintains performance, and the GME-S-eco series, an eco-friendly mist collector with the industry's highest air volume.

High-performance mist collector - GME-S-Pro series

Apiste 's high-performance mist collector, the GME-S-Pro series, features multi-step collection and positive pressure drainage, making mist collector maintenance-free for a long period of time. Furthermore, the industry's first split body allows for easy overhaul, maintaining performance for a long period of time.

In addition, the PM motor* and inverter allow for airflow control, making it energy-efficient. "filter and discs get clogging," "dirt accumulates inside," "it's difficult to disassemble"... This mist collector will eliminate the frustrations you may have had on the job site.

*400W is an induction motor

High-performance mist collector GME-S-eco series

Apiste 's high-performance mist collector, the GME-S-eco series, is mist collector that achieves high energy efficiency through a large-volume active cyclone and inverter-controlled airflow control.

Like the GME-S-Pro series, it uses a split body and is easy to maintain. This series is ideal for customers who want to improve oil mist environment while keeping energy costs down, or who want to improve on-site operations with simple regular maintenance.

Learn more about the GME-S-eco seriesApiste provides comprehensive support from before to after implementation

Technical support including model selection and required capacity calculations

Apiste 's sales and technical staff will meet with customers to make optimal proposals.

Free on-site inspection, free test equipment service

We will propose how to install the system on-site. We can also lend you a free test device so you can check the collection effect in advance.

Post-installation inspections and comprehensive after-sales support

As a hands-on company, we focus on after-sales service, such as inspections the products you install and dealing with errors.

At Apiste, dedicated sales and technical staff with extensive product knowledge act as a point of contact to support customers. With staff with specialized knowledge, we are able to respond quickly and accurately to any customer needs, questions, or inquiries. Even after mist collector is installed, we have a system in place to provide thorough after-sales support, including installation confirmations and regular equipment inspections.

InquiryApiste also offers a test machine rental service.

<Contents of the test device rental service>

Furthermore, Apiste offers a free test machine loan service so that customers can check the effects of implementation in advance.

First, our dedicated sales and technical staff will visit your site to select the most suitable model. After that, you will be asked to try out mist collector in your actual work environment. After a certain period of time has passed, we will visit you again to confirm with you the effectiveness of the test machine. If you are interested in mist countermeasures, please give it a try.

Test machine loan CCatalogApiste mist collector installation example

At Apiste, we provide comprehensive support from before to after installation to provide the best mist collector that meets your needs.

Case 1: oil mist collection from a horizontal machining center

A customer who had been having a major problem with oil mist scattering due to clogging of conventional mist collector adopted Apiste 's mist collector. mist collector captures oil oil mist in the optimal collection section according to the particle size, significantly reducing clogging, and the positive pressure drain that smoothly discharges the collected oil mist was highly praised.

Case 2: Collection of oil mist generated from a lathe

Apiste 's mist collector was introduced to address the problem of oil mist generated by lathes. With its advanced collection technology, it efficiently collects oil mist from lathes, contributing to maintaining a clean work environment. Compared to conventional systems, the system requires less maintenance and is highly rated for its ability to collect oil mist stably.

Apiste 's mist collector creates a clean factory environment!

This article provides detailed information about the types of mist collector and their installation methods. You can maximize the effectiveness of mist collector by selecting the model and installation method that best suits your individual work environment.

Apiste offers mist collector that meet the needs of each customer's environment. In particular, the "GME-S-Pro/eco series" is excellent in collection performance, ease of maintenance, and energy efficiency, meeting all needs. It can be equipped with an air conditioning filter, so it can capture even the finest mist.

Mist collector From post-delivery confirmation to regular inspections, our professional staff will provide you with solid support. We provide advice on model selection through on-site inspection and trial services with test machines, to meet the needs of each customer.

For inquiries regarding mist collector, please contact us using the form below.

Inquiry