Some vacuum pumps use oil, and they generate "oil mist" during operation. Leaving oil mist unattended can have an adverse effect on the factory environment, machinery, and equipment, so it's important to take appropriate measures. This article explains the causes of oil mist generation from vacuum pumps and the measures that can be taken. We also explain mist collector that are recommended for dealing with oil mist.

INDEX

Causes of oil mist from vacuum pumps

Vacuum pumps are devices that remove gases and come in several varieties, including types that use oil, such as "oil rotary vacuum pumps" and "oil diffusion pumps." The use of oil increases airtightness and makes rotational movement smoother.

However, when an oil-based vacuum pump exhausts air, oil mist is also emitted. oil mist can have an adverse effect on the working environment and machinery, so appropriate measures are required.

The danger of oil mist from vacuum pumps

- Impact on the work environment

- Impact on machinery and equipment

Oil mist generated by vacuum pumps can have an undesirable effect on the surrounding area. Let's take a look at the main effects.

The effects of oil mist on the human bodyImpact on the work environment

If oil mist generated by vacuum pumps is left unattended, it will adhere to the ceiling, walls, floors, etc. of the factory. Areas where oil mist has adhered will be more susceptible to dirt and dust, making environment even more unsanitary.

In addition, if oil mist accumulates on the ceiling, it can turn into oil droplets and fall. The oil droplets that fall and the oil that adheres to the floor can make the surface slippery, which can cause employees to trip or slip.

Impact on machinery and equipment

Oil mist generated by vacuum pumps can enter panel and air conditioning equipment in factories, causing machinery and equipment to malfunction more easily, clogging and corroding filter, and even causing problems in electrical systems.

Carefully removing oil mist can sometimes reduce the negative impact on machinery and equipment, but it is important to note that this takes time and money.

Countermeasures against oil mist in vacuum pumps

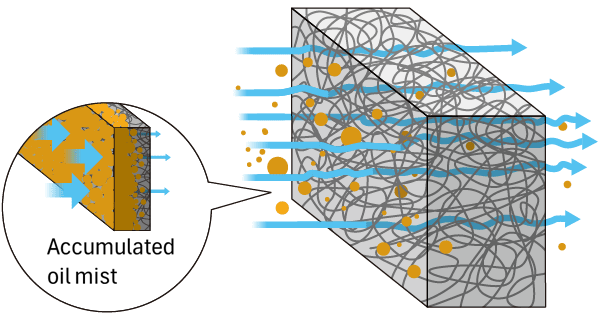

An effective way to deal with oil mist generated by vacuum pumps is to install an "oil mist trap." oil mist trap is filter is attached to the exhaust part of a vacuum pump.

When the air discharged from the vacuum pump passes through the built-in filter, it captures oil smoke and oil mist, preventing it from spreading outside. The oil captured by filter returns to a liquid and returns to the vacuum pump, preventing it from scattering into the air.

| Kinds | Features |

|---|---|

| Open type | This type disperses the air that passes through oil mist trap into the surrounding area. |

| Inline types | This type sends the air that has passed through oil mist trap to the outside using a device such as a duct. |

The open type oil mist trap dissipates the air filtered by the internal filter trap directly to the surroundings. In the case of an in-line type, a separate duct or other equipment is installed to send the filtered air to the outside. Select the appropriate type of oil mist trap according to the type of vacuum pump and exhaust volume.

Oil mist trap maintenance

The "element filter" inside oil mist trap can become clogged with oil as it continues to be used. If you continue to use it while it is clogged, the pressure inside oil mist trap will increase and it may burst, so caution is required.

Furthermore, a clogged oil mist trap will not be able to properly capture oil mist. This may result in oil and white smoke being emitted from around the pump. To ensure proper use of oil mist trap, be sure to regularly replace filter inside oil mist trap and manage the internal pressure.

- Oil mist trap maintenance

- Replace clogged filter with new ones

- Install a pressure gauge to monitor the pressure inside oil mist trap

Installing a "mist collector" is also important to prevent oil mist in factories.

Installing oil mist trap is an effective way to deal with oil mist from vacuum pumps. However, oil mist traps alone cannot completely remove oil mist that is generated. Also, if you are using machines that use oil, such as cutting machines or turning machines, in addition to vacuum pumps in your factory, there is a possibility that oil mist and oil smoke will be generated.

It is important to take measures against oil mist not only for the vacuum pump, but also for other machines and the entire space. Strengthen oil mist countermeasures by installing a "mist collector" that helps purify the entire space.

Create a comfortable environment with mist collectors!

High-performance mist collector can effectively capture oil mist of various sizes, ensuring a comfortable working environment and protecting the health of people working on-site.

What is a "mist collector" that is effective against oil mist?

oil mist and dust generated within a factory and separates them from the air.

Mist collector is a device used to maintain good air quality and environment in factories. It is used to separate oil mist that has been mixed into the air by evaporation or spraying from the air.

Mist collector are necessary to protect environment and machinery, and to promote production activities in factories. Installing mist collector also helps maintain the clean air in factories, which helps maintain the health of employees.

Main types of mist collector

Mist collector can be classified into four types based on their internal structure. Let's take a look at the features and mechanisms of each type.

| Collection method | Features |

|---|---|

Filter expression

|

This system captures particles through a physical filter. It has a simple structure and can be managed without specialized knowledge. filter needs to be replaced periodically. |

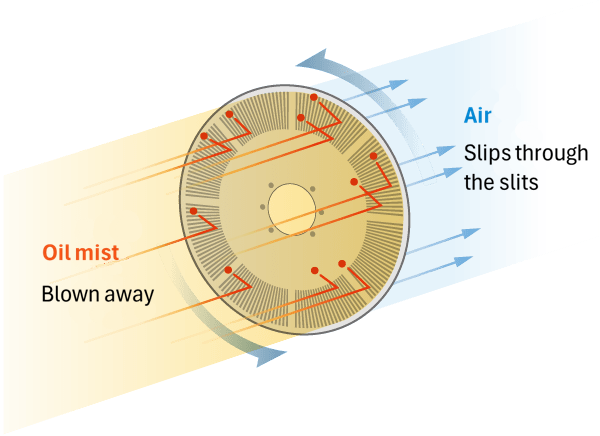

Disc type

|

The particles are collected by colliding with a disk that rotates at high speed. As there is no filter, there is an advantage that industrial disposal is not generated when filter replacement. |

Cyclone type (filter-less type)

|

It separates particles using centrifugal force. It is said that the particle size that can be collected by a general cyclone is only a few micrometers or more, and the collection efficiency is inferior to that of electric and disc types. However, the advantage is that there are fewer replacement parts. |

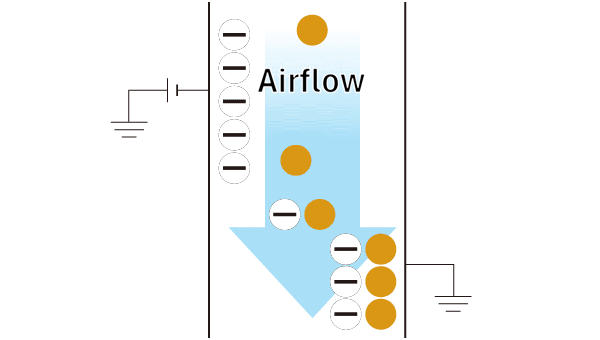

Electrostatic precipitator

|

It uses electrostatic force to adsorb and capture oil, and can capture even fine particles. However, the initial investment is high, and care must be taken when handling the high-voltage equipment. |

Apiste 's mist collector use a disk-type design that is easy performance maintain. If you are interested in the GME-S-Pro/eco series mist collector, which not only offer easy performance but also excellent collection performance and energy efficiency, please see below.

Implement oil mist countermeasures to keep the factory environment clean

Vacuum pumps can emit oil mist and oily smoke. Both not only pollute environment within the factory, but also have an undesirable effect on the machinery and environment, so care must be taken. Take measures against oil mist and keep environment within the factory clean.

If you have any questions about oil mist countermeasures or the introduction of mist collector, please feel free to contact us using the form below.