What is control panel heat exchanger?

control panel heat exchanger is a cooling device that exchanges heat between the air inside panel and the outside air, and releases the heat inside panel to the outside.

A cooling device similar to the control panel heat exchanger is the control panel cooling unit. Both are cooling equipment used to reduce the temperature inside the panel, but the control panel heat exchanger cannot cool to a lower temperature than the outside air because it provides cooling within the panel by exchanging heat with the panel outside air.

On the other hand, control panel cooling unit, like a home air conditioner, can cool the air in the panel to any temperature and keep it constant.

Both are devices that seal and cool the inside of the panel, but they must be selected according to the heat generation and installation environment in the cabin.

Types and principles of control panel heat exchanger

There are two types control panel heat exchanger: plate type and heat pipe type.

Plate type

The plate type has a structure in which metal plates are folded over, and heat exchange is achieved by indirect contact between the warm air and cold air inside panel. The large heat transfer area provides high heat exchange efficiency, but since a corresponding heat transfer area must be secured, the housing tends to be relatively large.

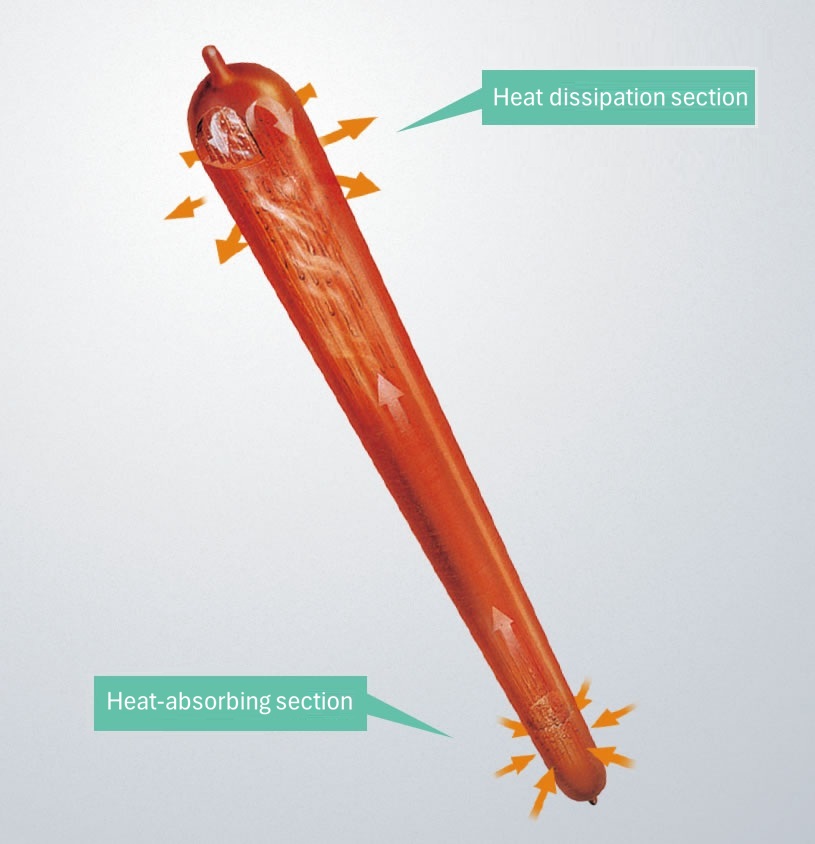

Heat pipe type

Pure water is sealed inside a vacuum pipe called a heat pipe, and heat exchange is carried out by utilizing the heat transfer caused by the evaporation and condensation of the pure water. Although it depends on the difference between the ambient temperature and the temperature inside panel, it has a relatively high heat exchange efficiency and is characterized by being smaller, lighter, and thinner than the plate type.

How to select a heat exchanger model

When selecting a heat exchanger model, first calculate the required rating capacity [W/K].

It is necessary to select a model with rating capacity greater than the calculated rating capacity.

Calculation method for required rating capacity

When calculating based on the amount of heat generated inside the panel

1. Determine the required numbers.

・Intra-board calorific value [Unit: W]

Total estimated calorific value of the equipment housed in the cabin

*Please refer to the list of calories generated by device in panel for the heat generation of each device.

- Maximum outdoor temperature [unit: °C]

The highest expected temperature in environment the device will be installed

- Allowable temperature inside the panel [unit: °C]

Allowable internal temperature

panel Effective Surface Area [Unit: m 2]

Surface area of the target panel (for freestanding panels, surface area excluding the bottom.)

2. Enter the above values into the formula below to calculate the required rating capacity.

[W/K]=

| Heat generation inside the panel [W] |

| Allowable temperature inside the panel [°C] - Maximum outside temperature [°C] |

*The heat transfer coefficient for a typical panel is usually 5.0 to 6.0.

When calculating based on the temperature inside the panel and the outside temperature

1. Determine the required numbers.

Temperature in the board (measured value) [Unit: °C]

Temperature inside the board of the target panel

- Outside temperature (measured value) [unit: °C]

Temperature of environment where panel is installed

- Maximum outdoor temperature [unit: °C]

The highest expected temperature in environment the device will be installed

- Allowable temperature inside the panel [unit: °C]

Allowable internal temperature

panel Effective Surface Area [Unit: m 2]

Surface area of the subject panel (for freestanding panels, surface area excluding the bottom)

2. Enter the above values into the formula below to calculate the required rating capacity.

[W/K]=

( |

Temperature inside the panel (measured value) [°C] - Outside air temperature (measured value) [°C] | -1 | ) |

| Allowable temperature inside the panel [°C] - Maximum outside temperature [°C] |

*The heat transfer coefficient for a typical panel is usually 5.0 to 6.0.

Once you have calculated rating capacity as above, select a model with rating capacity greater than that capacity.

We will select control panel heat exchanger that meets your requirements in 3 easy steps.

In this way, the selection of control panel heat exchanger requires calculations such as calculation of the calorific value of the board and the effective surface area of the panel, but in the Apiste" control panel heat exchanger Model Selection Guide", the required rating capacity is automatically calculated by entering the size of the panel, the storage equipment in the cabin, the desired temperature in the cabin, etc. You can choose the most suitable model.

If you are having trouble choosing a model or want to calculate the required rating capacity, please use our model selection guide.

*Membership registration is required to use this service.

Click here for a guide to selecting a control panel heat exchanger