Technical Information

3-1. Environment measures inside panel

This explains the need for and methods of environment measures inside panel.

(1) Evolution of FA and the increasing functionality and high-performance of control devices

In recent years, FA (Factory Automation) has become commonplace in production facilities. Within factories, robots and automatic machines are not only installed on the first floor, but are also installed all the way up to the mezzanine floor. This is a natural progression in order to reduce costs through mass production.

However, while low-cost mass production is possible, there are also disadvantages, such as the heat emitted by robots and automated machines having a negative effect on control devices. In particular, as electronic devices become smaller and more sophisticated, machines and panels are becoming even more downsized. Heat generation itself is on the rise, further affecting electronic devices.

Control equipment that has become faster, high-performance, and more functional has the positive side of increased efficiency through improved work speed, but the negative side is that it must be installed in environment that are unfavorable for control equipment, such as heat, dust, and humidity.

(2) Effects of trouble with control equipment

Now, let's take a look at how problems with control equipment affect actual production activities.

Case 1.

For example, if a panel stops working, even if it is only for 10 to 20 minutes, because the production line is an integrated system from the front-end to the back-end, not only the stopped panel but also the lines before and after it will be interlocked and the machines will stop.

Furthermore, if a furnace or other equipment stops, it will take 1-2 hours to restore operation. In other words, if the failure of one panel is taken into account, a loss of around 2 hours will occur.

Case 2.

For example, if your inverter stops working, replacing it will naturally require the cost of purchasing a new inverter. Just replacing the circuit board will likely cost several tens of thousands of yen.

If spare parts are not available, it may take several days, or even weeks, in some cases. If the inverter is old, it may no longer be manufactured. In the case of a long distance or an emergency, additional charter fees are required. Furthermore, if you keep inventory in case of an emergency, your inventory assets will increase. If you need to hire more maintenance staff for preventive maintenance and regular inspections, this will lead to higher labor costs, and you must be prepared for significant expenses.

The above-mentioned incidents occur every day at production sites. In the next section, we will introduce the effects of heat and humidity, which are common causes of sudden shutdowns of machines and panel.

(3) Effects of heat on equipment

Data has proven that heat significantly accelerates the failure rate of semiconductors and electronic components and shortens their lifespan. Graph 1 shows the temperature changes inside and outside panel of a certain automobile manufacturer. There is a temperature difference of approximately 15 to 20 degrees Celsius throughout the test.

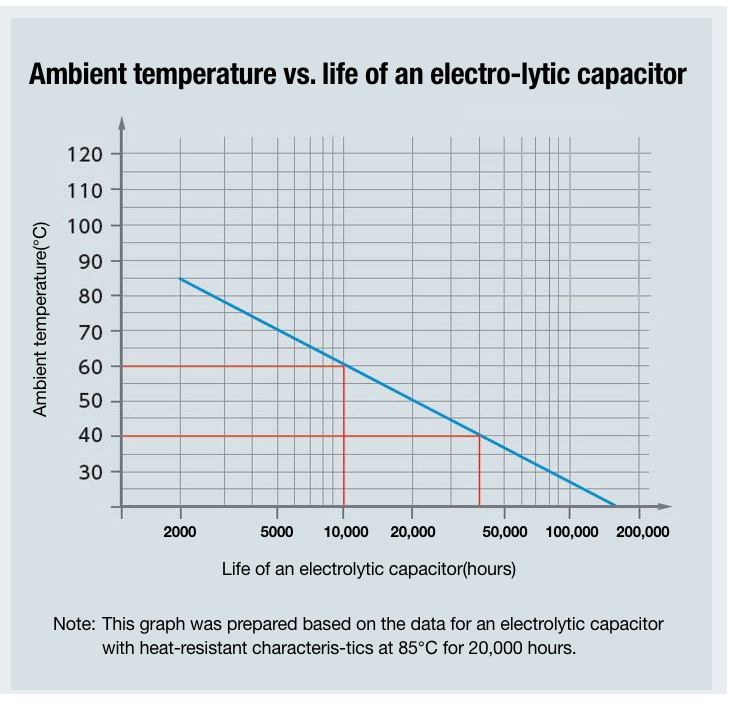

In panels where the temperature inside the panel reaches 55°C or 60°C, the lifespan of the capacitors used in electronic devices is significantly shortened, as shown in Graph ②.

Graph ② shows the relationship between the lifespan of an electrolytic capacitor and ambient temperature, known as the "10°C doubling rule." At a temperature of 30°C, the lifespan of an electrolytic capacitor is approximately 80,000 hours, but at a temperature of 40°C, it is 40,000 hours. In other words, it is halved. At a temperature of 60°C, it is one-quarter of that, or about 10,000 hours. The lifespan of semiconductors and electronic components is also significantly shortened by heat.

For every 10°C increase in temperature, the lifespan is halved

10℃ doubling rule

The graph on the right shows the relationship between the lifespan of electrolytic capacitors used in electronic devices and ambient temperature.

If the ambient temperature rises by 10°C, the life of an electrolytic capacitor will be halved.

As electronic devices become smaller and high-performance, the amount of heat they generate is on the rise, and panel that house them are also becoming smaller, so it is expected that temperatures inside panel that are not properly addressed will become even higher than before.

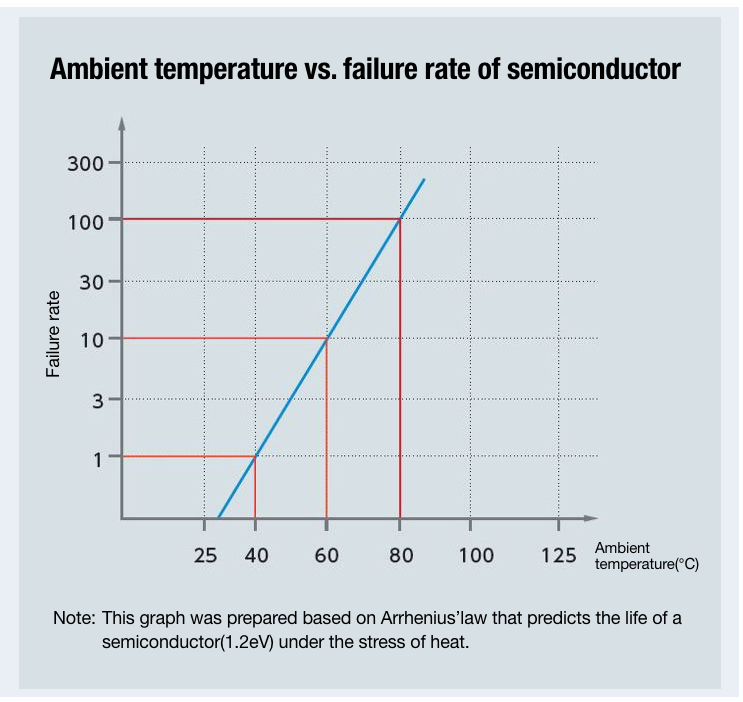

Furthermore, Graph 3 shows the relationship between the failure rate of semiconductors and ambient temperature, known as the "Arrhenius Law." According to this, the failure rate is very low at temperatures below 30°C, but at 40°C the failure rate is 1. At 60°C, this increases to between 10 and 30 times, and at 80°C it increases to between 100 and 300 times. This clearly shows how the failure rate of semiconductors and electronic components increases dramatically as the temperature rises.

As the ambient temperature rises, the failure rate increases exponentially.

Arrhenius's law

The graph on the right shows the relationship between the ambient temperature of a semiconductor and its failure rate.

If the relative failure rate at 40°C is assumed to be "1," it increases exponentially to "10" at 60°C and "100" at 80°C.

It is clear that permanent cooling of control equipment will continue to be an important factor in ensuring the continued stable operation of production lines.

(4) Effects of humidity on equipment

Along with heat, humidity is one of the causes of control equipment problems. Here we will consider how humidity affects control equipment.

Control equipment has many joints, and moisture is the enemy of joints. Graph ④ shows the relationship between corrosion and relative humidity, and we can see that corrosion progresses rapidly when the humidity exceeds 60%. In Japan, a humidity level of around 70% is generally considered normal, so humidity control measures for control equipment are extremely important. It is also said that the higher the temperature, the more corrosion progresses, so humidity control is an issue that must be considered at the same time as heat control measures.

(5) Conventional countermeasures and their problems

|

|

Panel FansThe effect is highly dependent on the surrounding environment.The effectiveness of this fan is greatly affected by ambient environment, and if the outside air temperature is high, you cannot expect much effect. Also, because the panel fan draws outside air into the panel, dust and oil mist can get in and cause problems. |

|

|

Heat ExchangerIt is not effective when the outside temperature is high.Unlike board fans, the panel can dissipate heat while being sealed, but since it uses the temperature difference between the inside and outside of the board, it is still not expected to have a significant effect when the outside air is high. Be careful as capacity may drop in the summer. |

|

|

Spot CoolerCondensation may occur due to rapid cooling.Although spot cooler are used as an emergency measure, they are originally designed for rapid cooling by workers, so there is a possibility of condensation when cooling electronic equipment. Also, because the panel is open, they cannot prevent dust or oil mist. |

|

|

Air Conditioning Duct BranchThere are differences depending on the distance, resulting in uneven temperatures.Due to the distance from the air conditioning and the heat generated in the cabinet, it is difficult to control the temperature individually for each panel, resulting in a very uneven cooling system. In addition, it takes time to branch the cooling duct, so it is not suitable for emergency heat countermeasures in the summer. |

(6) Benefits of using panel cooler

1) Cooling effect

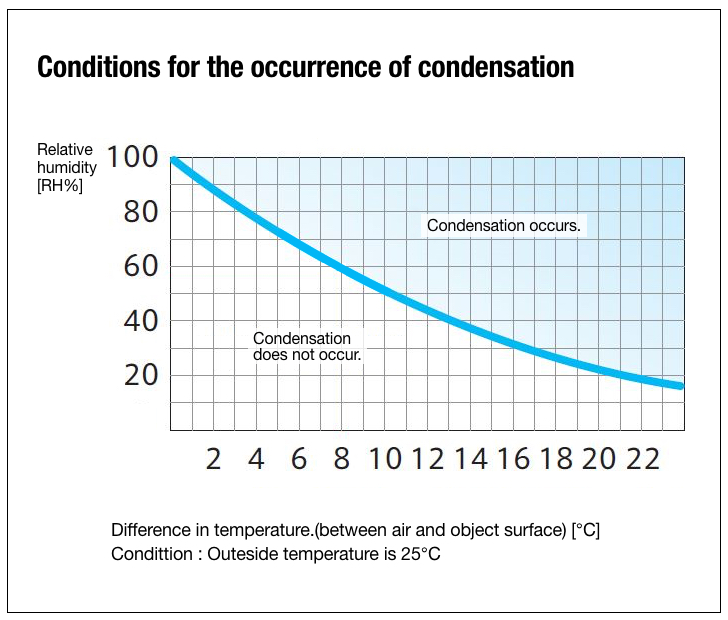

On the previous page, we mentioned that spot cooler have a low discharge temperature, but some may be wondering if the same is true for control panel cooling unit. A typical spot cooler is said to have a discharge temperature difference (the temperature difference between drawing control panel cooling unit and it is used under the typical temperature and humidity conditions of Japan's summer, there is a possibility of condensation. (Graph ⑤)

For this reason, Apiste has focused on its unique "mild cooling design" that prevents condensation by keeping the discharge temperature difference within 8°C, taking into account Japan's average summer humidity of 60%. By cooling slowly while dehumidifying, condensation is prevented. Every single component that makes up freezing cycle has been reviewed and the design of the unique refrigeration circuit has been adjusted. This has resulted in cooling that is gentle on electronic devices.

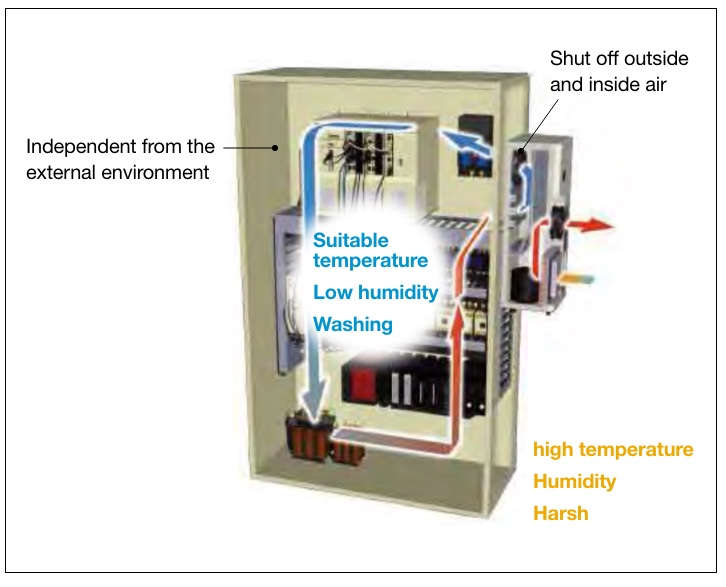

2) Dustproof effect

Because of the structure that completely separates the internal and external air, the panel with the cooler installed is spatially independent and sealed, and unlike board fans or outside air intake, it has a dustproof effect. This is why control panel cooling unit is introduced in oil mist and dusty environment.

3) Dehumidifying effect

When humid air passes through a cooling coil cooled by refrigerant, condensation occurs due to the temperature difference on the surface of the panel coil, and the water that is generated is discharged outside. This is dehumidification. This product improves the panel environment by preventing not only heat problems but also problems caused by moisture and dust.

Previous item: 2-3. Laws concerning fluorocarbons

People who viewed this page also checked out these documents:

Inquiry

For product inquiries, quote requests, etc.

Please feel free to contact us.