How to calculate the required cooling capacity for an outdoor panel

Basic points for selection

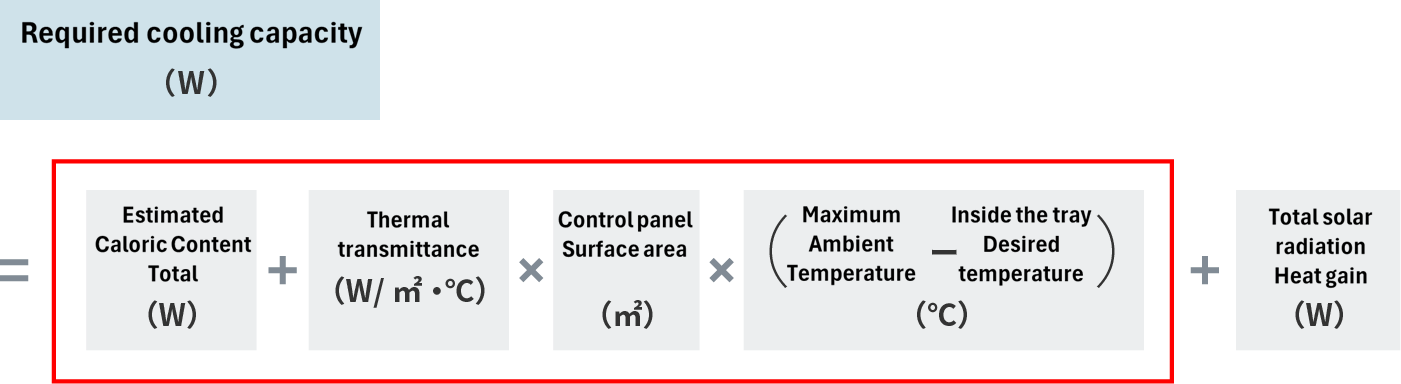

(1) In the red frame, check the following necessary information as in the calorie calculation method for indoor panel.

(e.g., estimated calorific value in the plate, effective surface area of panel, maximum ambient temperature, desired set temperature, etc.

→ more information, see the article "Basics of Selecting the Optimal cooler (Calculation of Calories, Calculation of Required cooling capacity)".

②For outdoor panel, the effect of direct sunlight must be taken into account, so the total amount of solar radiation entering the system must be calculated.

(W)=Equivalent rise in outside temperature

(℃)×heat transfer rate

(W/m 2 ・℃)×Surface area of each face

(m 2)

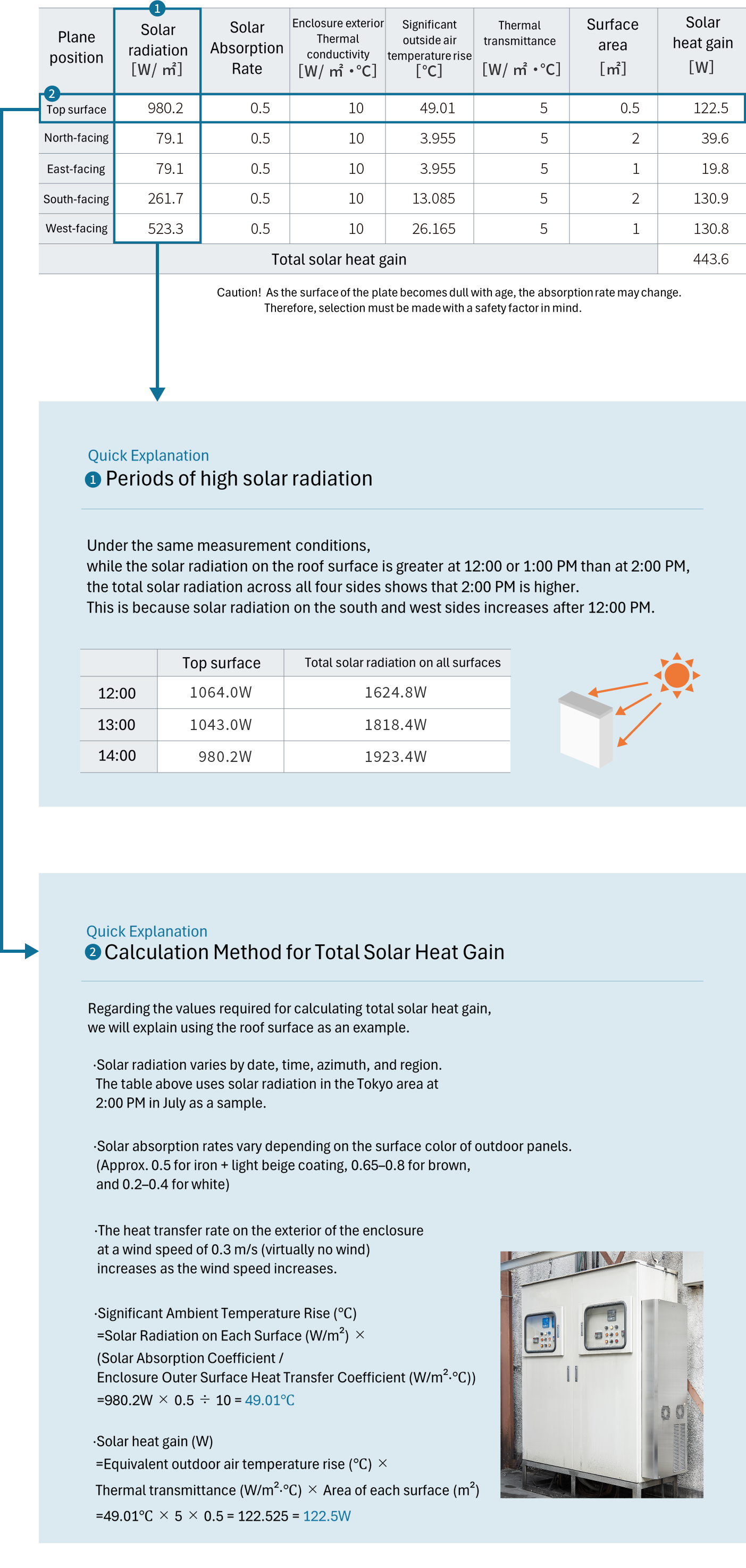

The equivalent outside temperature rise (℃) can be calculated using the formula: solar radiation on each surface (W/m²) x (solar absorptance/heat transfer coefficient of the outer surface of the enclosure (W/m²・℃)).

*Solar absorption rate: Varies depending on surface material, color, transmittance, etc.

*Heat transfer coefficient of the housing exterior: Approximately 10W/m²・℃ in windless conditions, and approximately 15W/m²・℃ when the wind speed is 1 to 2 m/s.

*Heat transfer coefficient: 2mm thick steel plate is approximately 5 [W/m²・℃]. The Panel Heat-Related Equipment Industry Association specifies it as 5 to 6 W/m²・℃.

The amount of solar radiation (= total solar infiltration heat) on an outdoor panel varies depending on the region and time of installation, the color/material/thickness of the casing surface, the casing structure (double structure, installation of sunshades, etc.), and the surrounding ventilation conditions.

*See Quick Explanation ①

As an example, let's calculate using panel with the following conditions.

◎ Height 2000mm, width 1000mm, depth 500mm

◎ Door facing south ◎ Tokyo area, July 22nd, clear skies, 2pm, no wind

◎Plate thickness: 2mm, paint color: light beige, wall surface is single-layered

The solar heat radiation for each surface is calculated using a formula.

Adding up the solar heat radiation from each surface, the total solar heat penetration is 443.6W.

*For details on calculating the heat quantity of an outdoor panel, Here Please see.

*The required cooling capacity for outdoor panel is calculated as follows: control panel cooling unit Model Selection Guide You can easily find it by.

Calculating the required cooling capacity for outdoor signage panels with glass surfaces

In recent years, outdoor digital signage advertising has been on the rise.

At the same time, there is an increasing need for cooling due to the risk of blackouts and breakdowns caused by high temperatures in computers, LCD monitors, etc.

Here are some points to keep in mind when using control panel cooling unit for an outdoor panel.

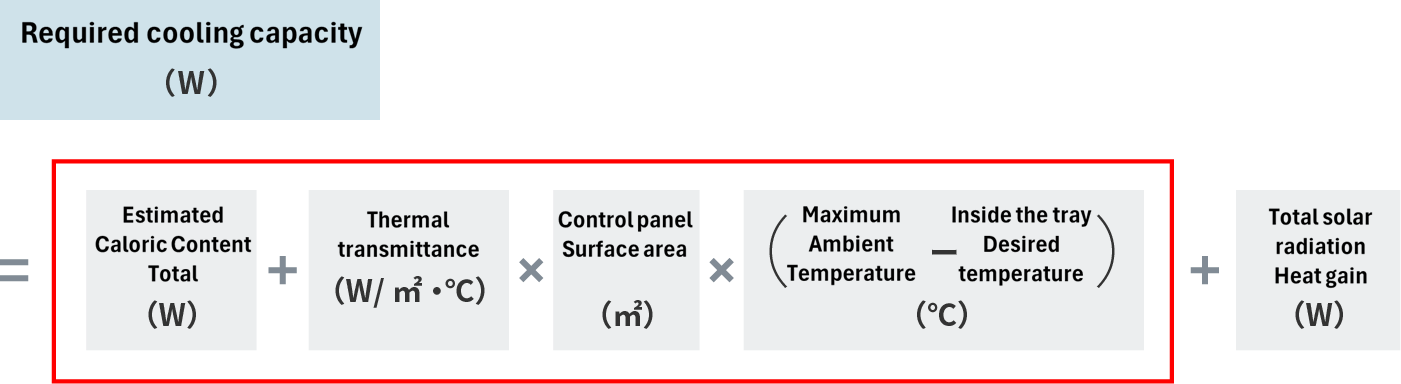

Concept 1: The method for calculating the required cooling capacity is basically the same as for outdoor panel, but the amount of solar heat entering the glass surface will change because it is made of a different material.

Total solar radiation intrusion heat (W) = Equivalent outdoor temperature rise (℃) x Overall heat transfer coefficient (W/m²/℃) x Surface area of each surface (m²)

Equivalent outside temperature rise (℃) = solar radiation on each surface (W/m²) x (solar absorptivity/heat transfer coefficient of the outer surface of the enclosure (W/m²・℃))

Concept 2: The amount of solar radiation on the glass surface needs to be estimated and corrected.

Concept 3: The solar absorption rate of the glass surface must be estimated and corrected.

Concept 4: The heat transfer coefficient of the glass surface on the exterior of the enclosure must be estimated and corrected.

Concept 5. As a result, a corresponding increase in outside temperature (℃) is required.

Let's Try!

Reference Procedure 1. The amount of solar radiation on the glass surface is calculated by using the amount of solar radiation on the outdoor panel.

Reference Procedure 2. The solar absorptance of the glass surface is set to approximately 0.7.

→ 0.7 is the midpoint between the values for clear double glazing and insulated double glazing. The value differs depending on the glass.

Reference procedure 3. The outer surface transmittance of the glass surface of the housing is set to approximately 2.5 (W/m²・℃).

→2.5 is the midpoint between the values of clear double glazing and insulated double glazing. The value varies depending on the glass.

Reference step 4. From the above, calculate the equivalent outside air temperature rise (°C).

Reference procedure 5. The heat transfer coefficient of the glass surface is approximately 2.0 (W/m²・℃).

→2.5 is the midpoint between the values of clear double glazing and insulated double glazing. The value varies depending on the glass.

Calculation example

Let's compare the calculation results for an outdoor steel plate surface and a glass surface.

*The calculation is based on the west side (523W) of the outdoor panel used as an example in the general catalogue and on the website.

Solar heat radiation on steel plate surface (W)

523W×0.5÷10 (W/m 2 ・℃) ×5 (W/m 2 ・℃) × 1 (m 2) ≒ 130.8W

Solar heat radiation on glass surface (W)

523W×0.7÷2.5 (W/m 2 ・℃) × 2 (W/m 2 ・℃) × 1 (m 2) ≒ 292.9W

The amount of solar heat radiation outdoors on the glass surface and steel plate surface increased by approximately 2.3 times.

*The above calculations are only a guideline. Actual results may differ depending on the glass material and installation location.

Recommended guideline

As a guideline, we recommend calculating the solar heat radiation for outdoor glass surfaces at least 2.5 times the normal amount.

*The above is a comparison with steel panels. Calculations for steel panels other than the glass surface are the same as before. When calculating the actual estimated cooling capacity, please take into account safety factor.