Technical Information

1-2. Cutting fluids and their effects

This explains the role of cutting oil, which is the source of oil mist.

(1) What is cutting fluid?

Cutting while pouring liquid on the food will help it cut better.

Wetting your knife a little will help you cut sushi rolls, cheese, etc. more smoothly.

This is because the lubricating effect of water reduces friction, which is also why roads become slippery on rainy days.

The same is true when cutting metal; by applying liquid while cutting, friction between the workpiece and the tool, and between the tool and the chips, is reduced, allowing for smoother cutting and reducing wear on the tool and workpiece.

During cutting, the temperature reaches nearly 1000°C

During cutting, the friction between the workpiece and the tool causes high temperatures.

When temperatures get high, the workpieces and tools expand and deform due to the heat, and the hardness of the tools decreases, causing them to wear out rapidly.

This will result in a decrease in the dimensional stability of the finished product.

Therefore, it is necessary to pour liquid on it to cool it down.

To put it simply, it's the same principle as when a car's engine burns out if there is no engine oil.

The liquid used in cutting is cutting oil

Cutting fluid is a liquid that acts as a lubricant and coolant during cutting. In addition to these two functions, it also has anti-welding, penetrating, rust-preventing and cleaning properties.

The three most important functions are lubrication, cooling, and anti-adhesion. Anti-adhesion prevents adhesion between the workpiece and the tool, and between the tool and the chips, due to the high temperature and pressure that occurs during cutting.

| Purpose | Work | Basic performance | ||||

|---|---|---|---|---|---|---|

| Jun Slippery Made by for |

anti melt Arrival Made by for |

cold Rejection Made by for |

rust Stop eye Made by for |

wash Clean Made by for |

||

| Improved dimensional stability | Suppression of tool friction | 〇 | 〇 | 〇 | ||

| Suppression of thermal expansion | 〇 | |||||

| Improved surface finish | Suppression of built-up edge | 〇 | 〇 | |||

| Reduced cutting force | Reduced friction | 〇 | ||||

| Extending tool life | Reduce tool wear | 〇 | 〇 | 〇 | ||

| Suppression of thermal degradation | 〇 | |||||

| Work efficiency | Chip disposal | 〇 | ||||

| Cooling of the workpiece | 〇 | |||||

| Improved quality | Rust prevention for workpieces and machine tools | 〇 | ||||

Is the main purpose lubrication or cooling?

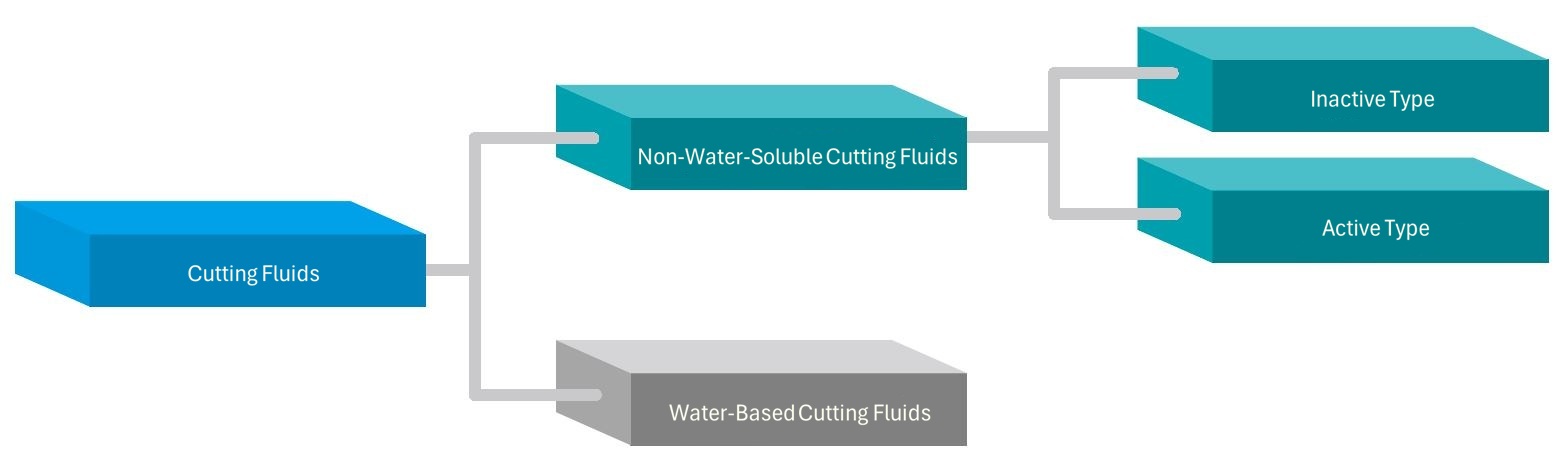

Cutting fluids can be broadly divided into water-insoluble cutting fluids that are used without diluting with water, and water-soluble cutting fluids that are used after dilution.

The main purpose of water-insoluble cutting fluids is lubrication and anti-welding, and they are used for cutting that requires high processing stability. The main purpose of water-soluble cutting fluids is cooling, and they have the advantage of reducing the risk of fire.

(2) Effects of each action

Lubricating effect improves cutting tool sharpness

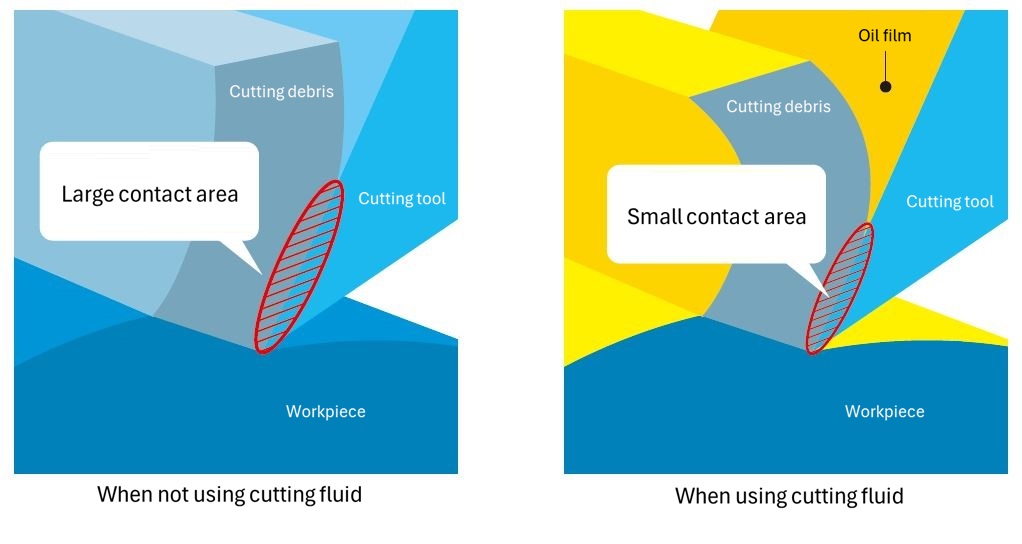

The lubricating effect of cutting fluid reduces wear on tools and workpieces. Let's take a closer look at this in more detail.

When a tool comes into direct contact with a workpiece, or metal to metal, the contact surfaces are not actually completely in contact, but have slight irregularities, and large forces are applied to the protruding parts of these irregularities, resulting in large friction.

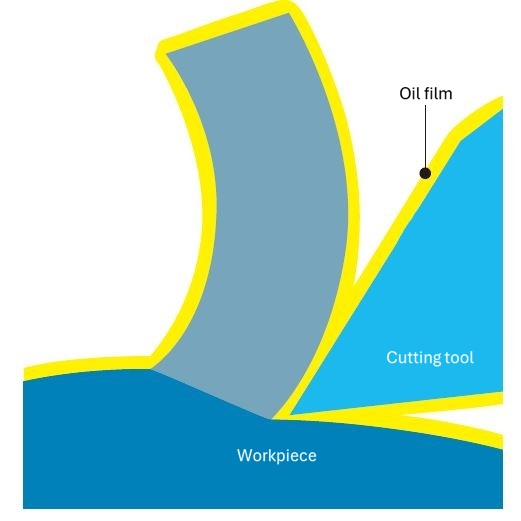

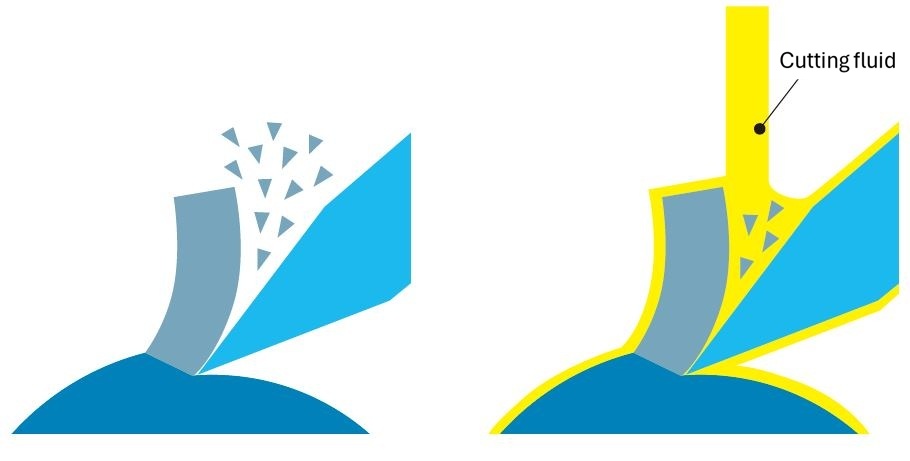

Therefore, cutting fluid is supplied to both the tool and the workpiece, creating an oil film on the metal surface to prevent direct contact between the metals and reduce friction and wear. This is the lubricating effect of cutting fluid.

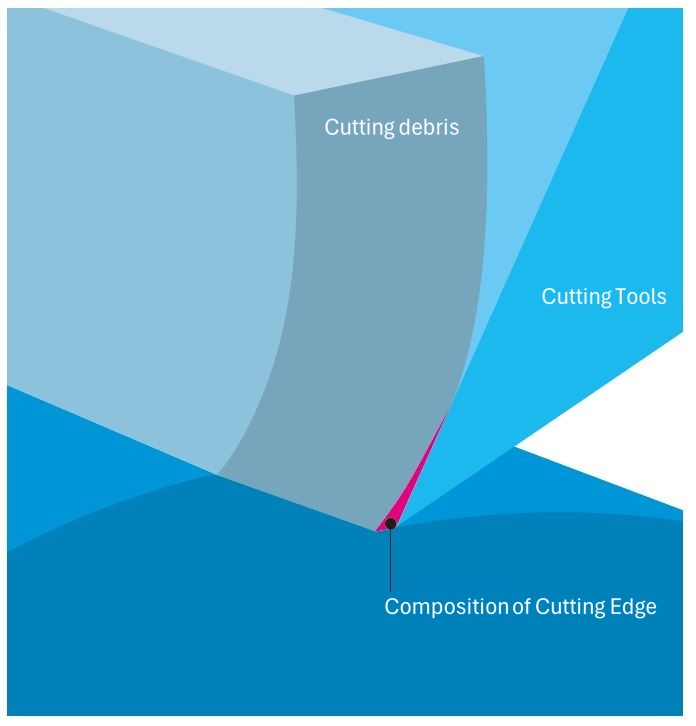

Also, chips are generated during cutting, and the smaller the friction between the chip-side surface of the tool (the rake face) and the contact surface of the chip due to the cutting fluid, the smaller the radius of curvature of the chip.

The smaller the radius of curvature, the smaller the contact area between the tool and the chip, resulting in better cutting performance.

Tool wear occurs due to friction during cutting, mainly caused by chips, and cutting fluid plays an important role in protecting the tool.

Cooling action reduces tool wear

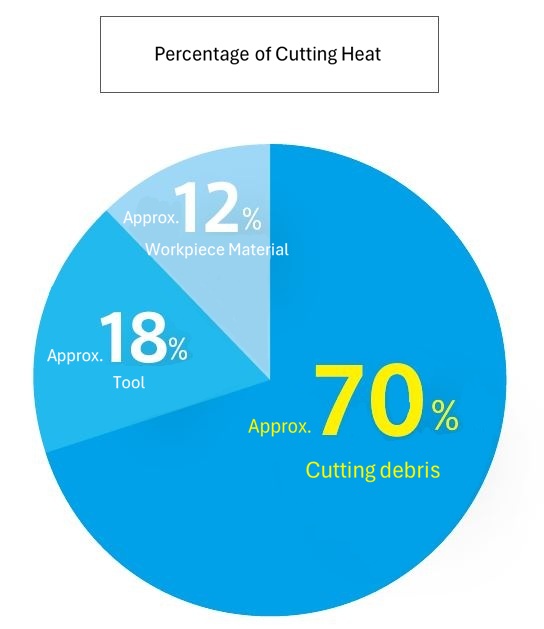

During cutting, the cutting temperature can reach 800°C or even 1000°C in some cases. Most of this heat is carried away by the chips, but it is also conducted to the tool, causing the temperature at the cutting edge to rise.

The cooling effect of cutting fluids prevents temperature rise, protecting tools from deformation and softening caused by heat, reducing wear and extending tool life.

The workpiece also becomes very hot, but the cooling effect prevents expansion and deformation due to heat, maintaining machining stability.

In addition, hot chips can be very dangerous as they can cause fires or cause burns when touched. The cooling effect also plays an important role in safety in such a work environment.

Protects tool cutting edges with anti-welding properties

During cutting, some of the chips melt and adhere to the cutting edge of the tool, forming a hard deposit. This is called a built-up edge. Because it adheres to the cutting edge, the finish stability of the workpiece becomes poor, and it can also peel off along with part of the cutting edge during cutting, causing tool deterioration.

This is particularly likely to occur in aluminum alloys, stainless steel, and heat-resistant alloys.

Cutting fluid protects the cutting edge with an oil film and prevents adhesion of the cutting edge.

Exhibits various effects through penetration

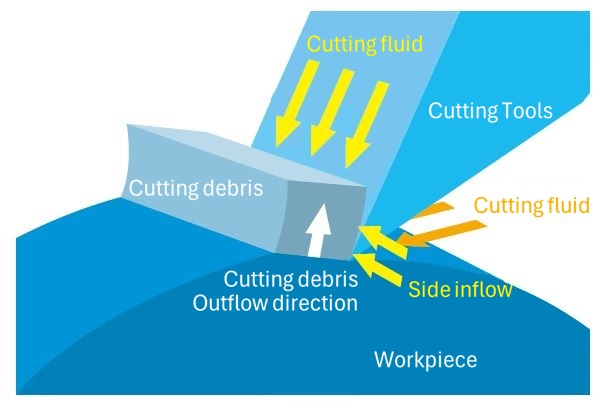

Cutting fluids are able to perform various functions such as lubrication and cooling because they penetrate into the gaps between the tool, workpiece, and chips.

Penetration varies depending on the type of cutting fluid.

Protects machines, tools, and workpieces with rust prevention properties

After cutting, the workpiece is susceptible to rust due to reaction with water and oxygen.

When cutting fluid is used, an oil film adheres to the surface, creating a protection film that prevents contact with water and air. In addition, water-soluble cutting fluids are increasingly being used due to environment concerns, and as they are more likely to affect not only the workpiece but also the tools and machine tools, it is becoming necessary to carefully consider the type and properties of cutting fluids.

Cleaning action reduces damage to tools

During cutting, cutting fluid is used to wash away chips and prevent them from getting caught between the tool and the workpiece or adhering to the workpiece.

It also prevents the fine chips generated during cutting from scattering around, helping to keep the work environment clean and safety.

Previous item: 1-1.Oil oil mist generation and its effects

Next item: 1-3. Types of cutting fluids

People who viewed this page also checked out these documents:

Inquiry

For product inquiries, quote requests, etc.

Please feel free to contact us.