Technical Information

1-4.How to choose cutting fluid

This explains how to select cutting fluids according to purpose, material, and processing method.

(1) Choose water-insoluble or water-soluble depending on your purpose

Choose the right oil for your work purpose.

Last time we explained that there are various types of cutting fluids, but how should you use them?

Broadly speaking, cutting fluids have cooling and lubricating properties, but it is important to select one based on its individual characteristics, taking into consideration the machining process, type of workpiece, and the work environment.

Cooling effect

- Suppressing the temperature of the workpiece...Maintaining and improving dimensional stability

- Suppressing the temperature of cutting tools...Maintaining and improving dimensional stability, maintaining machine stability, and extending tool life

Effects of lubrication

- Suppression of adhesion to cutting tools...improves the quality of the machined surface and extends the tool life

The oils used in grinding processes, which involve cutting with a grinding wheel, are called grinding oils, and they fight against the heat generated by friction. Depending on the purpose of the work, it is important to carefully consider which is more important: lubrication to suppress frictional heat, or cooling to remove generated heat.

Cutting Fluid Action

| Purpose | Improved dimensional stability | Improved surface finish | Reduced cutting force | Extending tool life | Work efficiency | Improved quality | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Work | Reduce tool wear | Suppression of thermal expansion | Suppression of built-up edge | Reduced friction | Reduce tool wear | Suppression of thermal degradation | Chip disposal | Cooling of the workpiece | Rustproofing of Workpiece / Machine tool |

|

| Basic performance | Lubrication | ○ | ○ | ○ | ||||||

| Anti-adhesive action | ○ | ○ | ○ | |||||||

| Refrigeration | ○ | ○ | ○ | ○ | ○ | ○ | ||||

| Anticorrosive action | ○ | |||||||||

| Cleaning | ○ | |||||||||

Grinding Fluid Action

| Purpose | Improve processing stability | Reduced cutting force | Extension of tool life | Work efficiency | Improved quality | ||||

|---|---|---|---|---|---|---|---|---|---|

| Work | Suppression of crushed and spilled eyes |

Suppression of thermal expansion | Suppression of blindness and clogging |

Suppression of crushed and spilled eyes |

Chip disposal | Cooling of the workpiece | Prevention of burning and cracking | Rustproofing of Workpiece / Machine tool |

|

| Basic performance | Lubrication | ○ | ○ | ○ | ○ | ||||

| Anti-adhesive action | ○ | ○ | ○ | ||||||

| Refrigeration | ○ | ○ | ○ | ○ | ○ | ○ | |||

| Anticorrosive action | ○ | ||||||||

| Cleaning | ○ | ○ | |||||||

Choosing between water-insoluble and water-soluble

If lubrication and anti-welding properties are important, water-soluble oils are generally chosen, while if cooling properties are important, water-soluble oils are generally chosen. Simply put, if sharpness is important, water-soluble oils are preferred, and if cooling properties are important, water-soluble oils are preferred.

In addition, water-soluble oils containing surfactants are superior in terms of penetration and cleaning properties, but water-insoluble oils that do not contain water are superior in terms of rust prevention and resistance to deterioration.

Cutting Fluid Characteristics

| Characteristics Type (JIS classification) |

Lubricity | Anti-welding | Coolability | Permeability | Cleanability | Effervescence | Rust Resistance | Corruption resistance | Degradation resistance | Operability | Flammability Hazard | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Insoluble cutting fluid | Oil-based type (N1 type) |

○ | ○ | × | ○ | × | ★ | ★ | - | ★ | × | Yes |

| Inert extreme pressure type (N2, N3 type) |

★ | ★ | × | ○ | × | ★ | ★ | - | ★ | × | ||

| Active extreme pressure type (N4 type) |

★ | ★ | × | ○ | × | ★ | ★ | - | ★ | × | ||

| Water soluble cutting fluid | Emulsion (Type A1) |

○~× | × | ○ | ○ | ○ | ○ | × | × | × | × | Nothing |

| Soluble (A2 type) |

× | × | ★ | ★ | ★ | × | ○ | ○ | ○ | ○ | ||

| Solutions (A3 type) |

× | × | ★ | × | × | ★~○ | ○ | ★ | ○ | ★ | ||

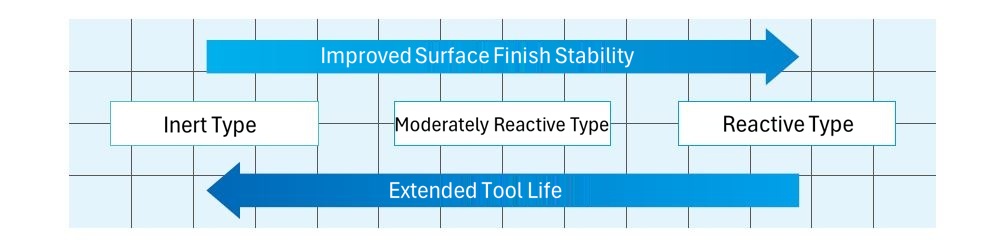

How to choose a water-insoluble oil

Water-insoluble oils are broadly divided into "oil-based," "inactive extreme pressure," and "active extreme pressure" types. If tool life is important, the inactive type is suitable, while the active type is suitable for improving the quality of the machined surface.

Also, by work material, as shown in the diagram below, the selection must be made according to the purpose of the work. For example, oil-based drills with moderate lubrication are suitable for carbon steel, alloy steel, cast iron, and aluminum alloys, while extreme pressure drills with excellent anti-welding properties are suitable for work materials prone to welding, such as stainless steel and heat-resistant steel.

How to choose a water-soluble oil

Water-soluble oils are primarily excellent at cooling, but the choice also depends on whether you prioritize cooling or lubrication. If cooling is the priority, you should choose a soluble or solution type, and if lubrication is the priority, you should choose an emulsion type.

It is also necessary to select the product according to the purpose for each work material. For example, emulsions are suitable for steel, which requires lubrication, solubles for cast iron, which requires cooling properties, and emulsions containing extreme pressure additives that increase anti-welding properties are suitable for work materials that are prone to welding, such as stainless steel and heat-resistant steel.

(2) Selecting cutting fluid for each workpiece

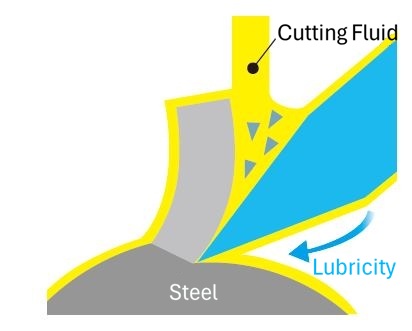

steel

- When machining stability is required, a water-insoluble oil containing extreme pressure additives that enhance lubricity is used.

- If you use water-soluble oil, use an emulsion type that has high lubricity.

- For heavy cutting, use an emulsion type that contains extreme pressure additives.

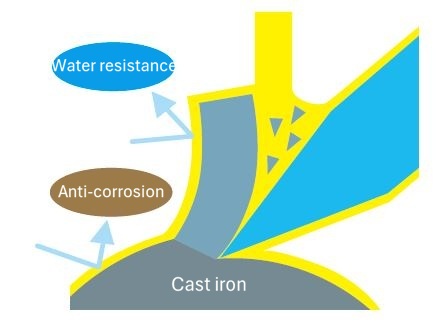

Cast iron

- Water-insoluble oils that can prevent rust include oil-based and inert extreme pressure oils.

- If you use a water-soluble oil, it should have excellent rust-preventing properties.

- In the case of ductile cast iron, this oil has excellent resistance to hard water, taking into account the increase in hardness of water-soluble oils over long-term use.

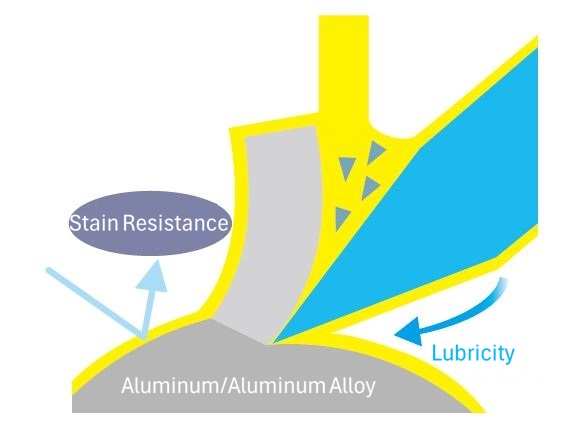

Aluminum and aluminum alloys

- In the case of water-insoluble oils, oil-based oils.

- A highly lubricating emulsion-type water-soluble oil is used for work materials that are soft and prone to adhesion.

- In the case of water-soluble oils, choose oils that inhibit discoloration.

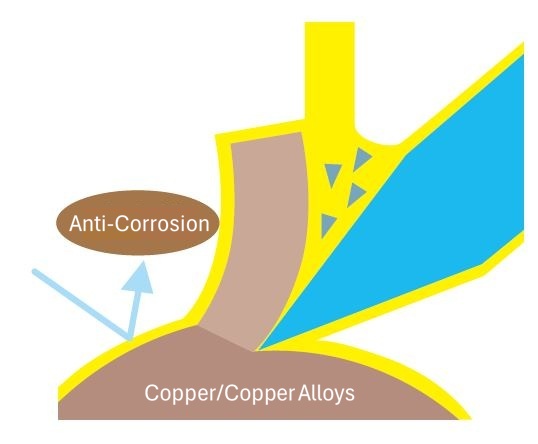

Copper and copper alloys

- Be careful when using oils containing sulfur-based extreme pressure additives as they can cause corrosion.

- In the case of water-soluble oils, they should be anti-corrosive.

(3) Cutting oil selection for each processing method

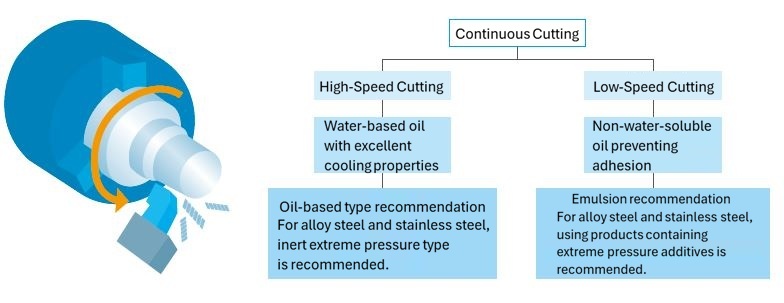

Continuous cutting/intermittent cutting

Last time, we focused on how to select cutting fluids based on the workpiece material, but it is also necessary to consider the processing method.

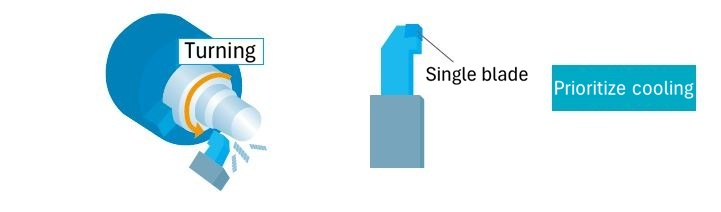

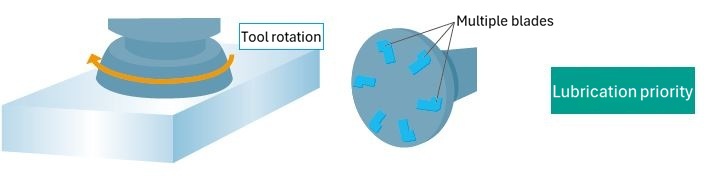

For example, in lathe machining, when a single-blade (one blade) cutting tool is in continuous contact with the rotating workpiece, it is called continuous cutting, and in milling, when a multi-blade (multiple blades) cutting tool acts repeatedly (intermittently) on a fixed workpiece, it is called intermittent cutting.

In continuous cutting, the cutting tool is constantly in contact with the workpiece, so heat caused by friction tends to accumulate at the cutting edge, making an oil with excellent cooling properties suitable.

On the other hand, in the case of intermittent cutting, a large impact occurs when the cutting tool hits and bites into the workpiece, so an oil with excellent lubrication properties is suitable.

Continuous cutting: Machining in which the blade is in continuous contact with the workpiece

Intermittent cutting: A process in which the cutting edge repeatedly comes into contact with and separates from the workpiece.

The optimum oil for each processing method

In turning

Last time, we focused on how to select cutting fluids based on the workpiece material, but it is also necessary to consider the processing method.

For example, in lathe machining, when a single-blade (one blade) cutting tool is in continuous contact with the rotating workpiece, it is called continuous cutting, and in milling, when a multi-blade (multiple blades) cutting tool acts repeatedly (intermittently) on a fixed workpiece, it is called intermittent cutting.

In continuous cutting, the cutting tool is constantly in contact with the workpiece, so heat caused by friction tends to accumulate at the cutting edge, making an oil with excellent cooling properties suitable.

On the other hand, in the case of intermittent cutting, a large impact occurs when the cutting tool hits and bites into the workpiece, so an oil with excellent lubrication properties is suitable.

In milling

Milling is a machining method that uses a milling machine to bring a rotating cutting tool into contact with the workpiece. Cutting tools used include end mills, face mills, and flat mills.

Cutting tools have many blades, so they perform intermittent cutting, which causes large impacts and large temperature changes at the cutting edge (thermal shock), making the cutting edge more susceptible to chipping.To prevent this, it is best to use dry cutting without using cutting fluid or water-insoluble fluid.

Drilling

When drilling holes, the direction in which chips are discharged and the direction in which cutting fluid flows are opposite, making it difficult for the cutting fluid to reach the cutting point.

Therefore, cutting fluid with high permeability is required, which can reach deep into the hole against the flow of discharged chips.

For water-insoluble oils, oil-based types are suitable, while for water-soluble ones, soluble or synthetic types are suitable.

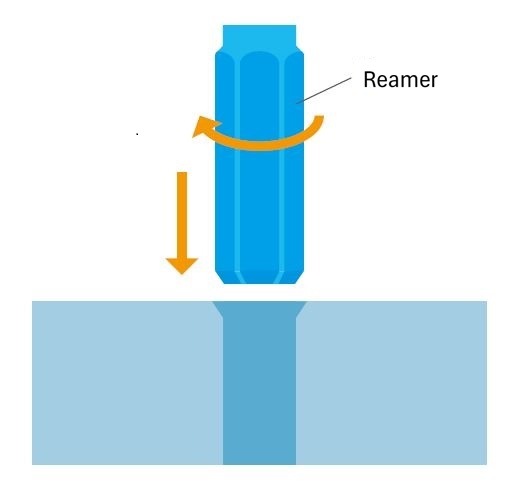

Reaming

Reaming is a process that finishes holes made with a drill or other tool with higher stability.

Because of the high stability required, cutting fluids with excellent lubricity are used, and low-viscosity, water-insoluble fluids that generally contain extreme-pressure additives are used to prevent tool wear and built-up edge.

In particular, active extreme pressure types containing active sulfur are suitable for alloy steel and stainless steel, while oil-based types are suitable for aluminum alloys.

For water-soluble oils, emulsions with high lubricity are common, but for alloy steel and stainless steel, emulsions containing extreme pressure additives are suitable.

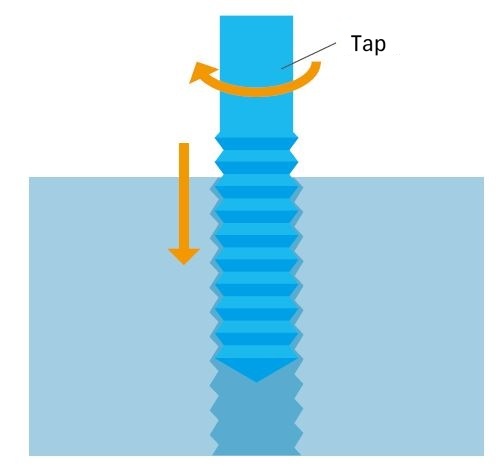

Tapping

Tapping is the process of drilling a screw hole using a tap (cutting tool). Because the friction between the tap and the workpiece is large, a water-insoluble oil with excellent lubrication and anti-adhesion properties is suitable.

The details are the same as those for the cutting fluids recommended for reaming.

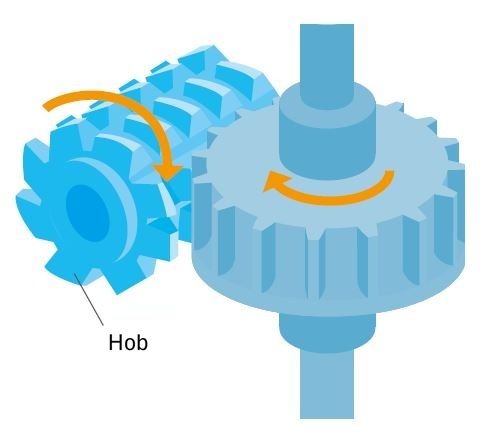

Gear cutting

Gear cutting is the process of cutting the teeth of a gear.

The friction between the cutting tool and the chips increases, requiring high lubrication. Generally, dry machining or water-insoluble oils are suitable.

In addition, for finishing processes (shaving), low viscosity, water-insoluble oils are used as stability is required.

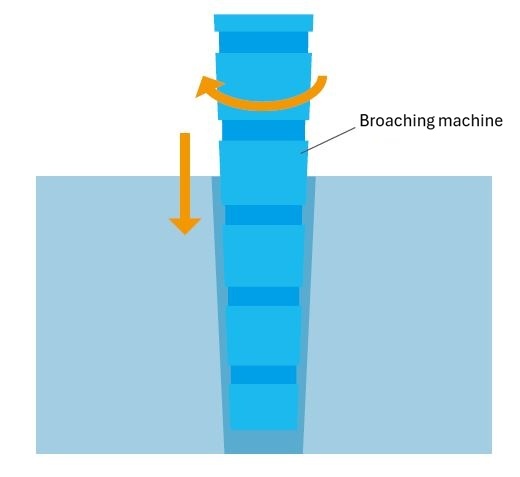

Broaching

Broaching is a process in which the inner surface of a hole or the surface of a workpiece is cut using a cutting tool called a broach, which has a rod-shaped shaft with many circular blades arranged in a saw-like pattern.

Since both tool life and machining stability are required, water-insoluble oils containing extreme pressure additives are generally used.

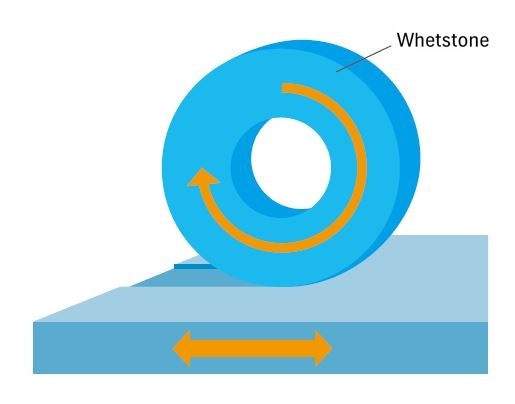

Grinding

Grinding is a process in which the surface of a workpiece is scraped using a grinding wheel that rotates at high speed. Because much of the heat generated is stored in the workpiece, the material must have excellent lubrication and cooling properties to reduce frictional heat, and it must also be permeable (cleanable) to prevent clogging.

Generally, water-soluble oils suitable for cooling are used, and solubles with excellent lubricity and penetration properties are used.

Oil selection list for each processing method

| Oil-based (or greasy) type | Inert extreme pressure type | Active polarized pressure form | Emulsion | Soluble (including micro emulsions) |

Solution | ||

|---|---|---|---|---|---|---|---|

| Basic performance | Lubricity | ○ | ★ | ★ | ○~× | × | × |

| Anti-welding | ○ | ★ | ★ | × | × | × | |

| Coolability | × | × | × | ○ | ★ | ★ | |

| Permeability | ○ | ○ | ○ | ○ | ★ | × | |

| Cleanability | × | × | × | ○ | ★ | × | |

| Carbon steel and alloy steel | Turning and boring | ○ | ○ | ○ | |||

| Drill ring | ○ | ○ | ○ | ○ | ○ | ||

| Reaming | ○ | ○ | |||||

| Tapping | ○ | ○ | ○ | ||||

| Milling | ○ | ○ | ○ | ||||

| Brooch | ○ | ||||||

| Gnashing the teeth | ○ | ○ | |||||

| Grinding | ○ | ○ | ○ | ○ | ○ | ||

| Honing | ○ | ○ | |||||

| Superfinishing | ○ | ||||||

| Stainless steel | Turning and boring | ○ | ○ | ○ | |||

| Drill ring | ○ | ○ | ○ | ||||

| Reaming | ○ | ○ | |||||

| Tapping | ○ | ○ | |||||

| Milling | ○ | ○ | |||||

| Brooch | ○ | ||||||

| Gnashing the teeth | |||||||

| Grinding | ○ | ○ | |||||

| Honing | |||||||

| Superfinishing | ○ | ||||||

| Cast iron | Turning and boring | ○ | ○ | ||||

| Drill ring | ○ | ○ | ○ | ||||

| Reaming | ○ | ○ | |||||

| Tapping | ○ | ○ | |||||

| Milling | ○ | ○ | ○ | ||||

| Brooch | ○ | ||||||

| Gnashing the teeth | ○ | ||||||

| Grinding | ○ | ○ | ○ | ||||

| Honing | ○ | ○ | ○ | ||||

| Superfinishing | |||||||

| Aluminum alloy | Turning and boring | ○ | ○ | ○ | |||

| Drill ring | ○ | ○ | ○ | ||||

| Reaming | ○ | ○ | ○ | ||||

| Tapping | ○ | ○ | ○ | ||||

| Milling | ○ | ○ | |||||

| Brooch | |||||||

| Gnashing the teeth | |||||||

| Grinding | ○ | ○ | |||||

| Honing | ○ | ○ | |||||

| Superfinishing | |||||||

(4) Summary of how to choose cutting oil

When selecting cutting fluid, multiple factors come into play, such as the work material, processing method, tool material, processing stability, tool life, working environment, and the global environment (eco-friendliness). Therefore, it is important to clarify priorities such as "priority stability," "priority on tool life," and "priority on the working environment," and to formulate a basic policy.

(1) Establish basic policy: Clarify priorities such as "accuracy first," "tool life first," "work environment first," etc.

2) Confirmation of preconditions: What is the work material, tool, machining method, etc.?

3) Selection and comparison of candidate lubricants: Select lubricants based on past performance and manufacturer recommendations, and compare their performance.

4) Selection - Verification: Using the most suitable oil, conduct trial cutting and verification. If any defects are found, additives are added or other adjustments are made.

5) Decision

Previous item: 1-3. Types of cutting fluids

Next item: 1-5. Cutting fluids and working environment

People who viewed this page also checked out these documents:

Inquiry

For product inquiries, quote requests, etc.

Please feel free to contact us.