Technical Information

1-5. Cutting fluids and working environment

This explains the health effects of cutting oil splashes and how to prevent splashes.

(1) Health effects of oil spills

Oil scattering worsens the working environment

Cutting fluids have a significant impact on the working environment. The oil oil mist that is dispersed during cutting processes not only stains floors and walls, but also has an adverse effect on the health of those who handle or process the fluid.

In addition, it cannot be denied that substances contained in cutting oils may be carcinogenic, and that in the case of chlorine-based cutting oils, dioxins may be generated when chlorine is burned during processing, which could cause health problems.

Prevents skin contact

When cutting fluid comes into contact with the skin, irritation from the oil and degreasing from the surfactants can cause a rash, although this varies from person to person. It can also occur not only on exposed skin, but also when the oil soaks into work clothes and the clothes come into contact with the skin.

As a preventative measure, wear gloves, a mask, a hat, etc., and minimize skin exposure as much as possible. It is also effective to wash your hands and face frequently with mild soap before and after work, and to apply protection cream. As for clothing, try to wash it every day, always wear clean clothes, and always wear underwear to prevent direct contact between work clothes and your skin.

Also, if the cutting oil has deteriorated or become rotten, the irritation will be even stronger, so be sure to manage the cutting oil carefully.

Protect your eyes from splashes

If flying cutting fluid gets into your eyes, it can cause inflammation just like it does on your skin. To prevent this, always wear protection glasses protection your eyes when processing. If it gets into your eyes, rinse them immediately with water.

Care must be taken as the scattered cutting oil may contain tiny chips.

Prevents odors and inhalation

The smell of cutting fluid or inhaling scattered cutting fluid can make you feel sick or give you a headache. Inhaling it can also cause inflammation of the nose and throat. To prevent these, it is effective to wear a mask at the work site.

(2) Methods for preventing cutting fluid from scattering

1. Preventing scattering itself

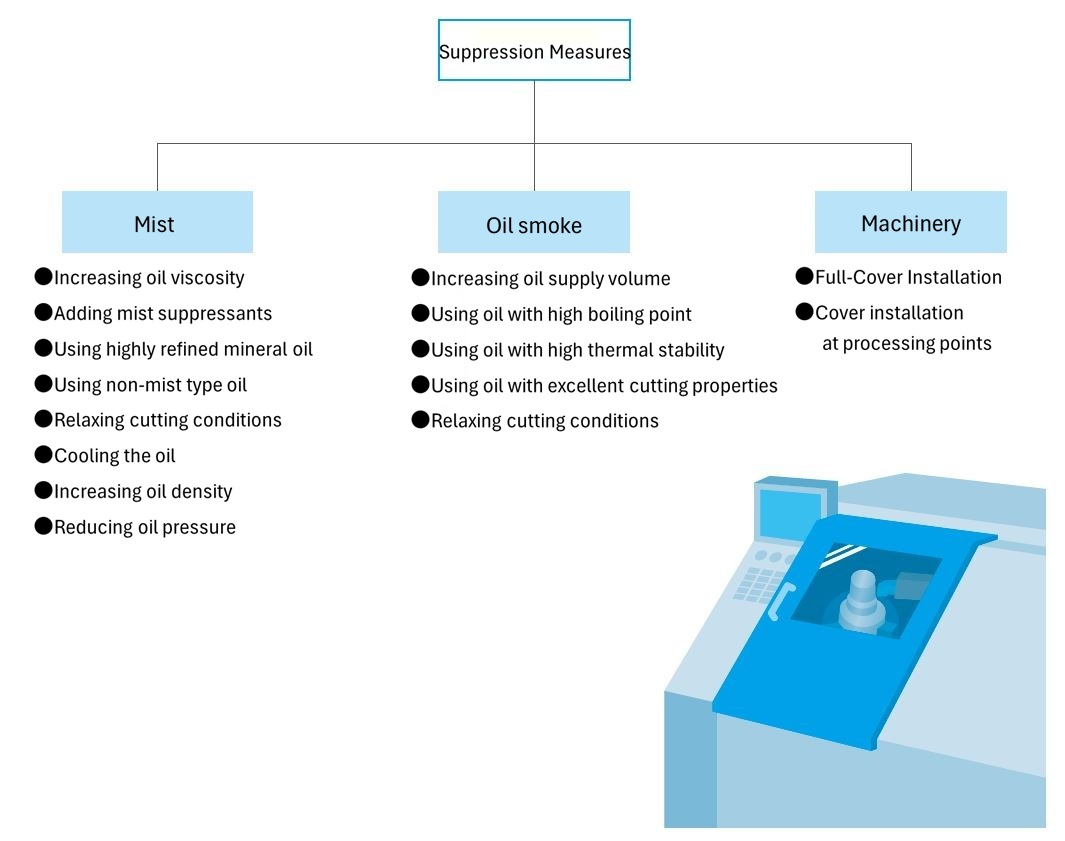

To improve the working environment, it is first necessary to suppress the scattering of cutting fluid and the generation of oil smoke. As a countermeasure, first consider reviewing the type of fluid (increasing viscosity, adding mist suppressants, etc.) and the amount supplied, as well as easing the cutting conditions. It is also necessary to cover the entire machine and the machining points of the machine.

2. Collect the scattered oil

Although various control measures can be implemented to reduce the amount of oil that scatters, it cannot be eliminated. In other words, recovery work is required. Methods for recovery include installing ducts on the machine, installing mist collector, or a combination of both.

mist collector installed in the fully covered machine sucks up the oil oil mist that has scattered inside the machine and prevents it from leaking to the outside by creating a negative pressure inside the machine. Inside mist collector, oil mist is separated from the sucked air and the air is purified before being discharged.

Previous item: 1-4.How to choose cutting fluid

Next item: 1-6. Hazardous material classification of water-insoluble cutting fluids

People who viewed this page also checked out these documents:

Inquiry

For product inquiries, quote requests, etc.

Please feel free to contact us.