Technical Information

1-3. Types of cutting fluids

This explains the types of cutting fluids and the characteristics and classification of each type of fluid.

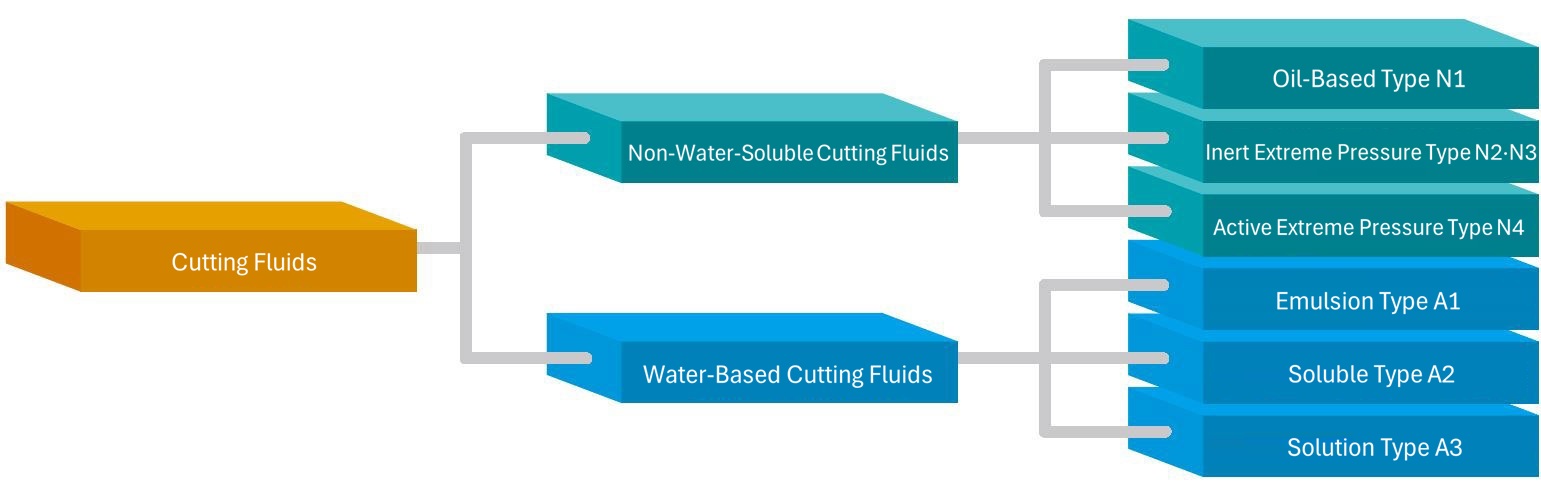

(1) Water-insoluble cutting oil and water-soluble cutting oil

They are broadly divided into two categories: water-insoluble and water-soluble.

As I mentioned briefly last time, cutting fluids can be broadly divided into water-insoluble cutting fluids that are used without diluting with water, and water-soluble cutting fluids that are diluted and used.

Characteristics of water-insoluble oils

- Suitable for light cutting of non-ferrous metals that are prone to corrosion.

- It has excellent lubricity and anti-adhesion properties, which prevents built-up edges and makes it suitable for machining alloy steel and difficult-to-cut materials that require stability.

- Because it is flammable, care must be taken when cutting or storing it. It is subject to the Fire Service Act.

- High temperatures can easily generate oil smoke, oil mist countermeasures are necessary.

Characteristics of water-soluble oils

- It has a high cooling effect and is suitable for high-speed cutting.

- Rust prevention measures are required for workpieces and tools.

- Management requires measures to prevent decay and deterioration caused by bacteria, etc.

- It is non-flammable and is therefore suitable for unmanned factories. It is not subject to the Fire Service Act*.

- It is cost-effective because it is diluted with water.

*Not all water-soluble oils are exempt from the Fire Service Act.

(2) Characteristics and classification of water-insoluble cutting oils

The components are base oil + additives

The main component of the base oil is mineral oil, but it also contains synthetic oils and fatty acids.

What is mineral oil?

This oil is made by compressing and distilling crude oil and refining it to remove impurities. It has fluid lubrication performance, and light cutting can be done with mineral oil alone.

What is synthetic oil?

Also known as synthetic lubricants, they are chemically synthesized compounds that complement performance mineral oils lack. They have excellent lubrication properties.

What are Fatty Acids?

Also known as fats and oils, they are liquid at room temperature. Rapeseed oil, castor oil, palm oil, etc. are used. Because they are highly biodegradable, their use is increasing in consideration of environment.

Additives are used to restore or supplement performance of base oils or to impart specific performance.

Additives List

| additives | compound | effect |

|---|---|---|

| Oily agent | Fatty oils, fatty acids, esters, higher alcohols | Reduced friction and wear |

| Extreme Pressure Additives | Sulfur compounds, phosphorus compounds, organic metal compounds | Friction, wear and seizure prevention |

| antioxidants | Sulfur compounds, phenolic compounds, amine compounds | Antioxidant |

| Rust inhibitor | Sulfonates, carboxylates | Prevents rust from forming |

| Corrosion inhibitors | Benzotriazole, sulfur-based compounds | Corrosion prevention |

| Corrosion prevention | polymer compound | Suppression of oil mist |

| Pour Point Depressants | polymer compound | Maintaining the fluidity of mineral oil |

| Viscosity index improver | polymer compound | Improving the viscosity of mineral oil |

| Antifoaming agents | Silicone oil | Preventing foam destruction and formation |

Classification according to JIS standards

Water-insoluble oils are classified into "N1" to "N4" depending on whether they contain extreme pressure additives and whether they corrode copper plates.

Extreme pressure additives are additives that increase the strength of the oil film between friction surfaces, reduce friction and wear, and prevent seizure of the lubricated surfaces.

Copper plate corrosion is a standard determined by testing the corrosiveness of copper plates, with a score of "1" meaning the copper plate is "slightly discolored," "2" meaning "moderately discolored," "3" meaning "deeply discolored," and "4" meaning "corroded."

| Extreme Pressure Additives | Copper plate corrosion | Mineral oil ratio | Purpose | |

|---|---|---|---|---|

| Oil-based N1 pole (No. 1 to 4) |

none | ― | 60~95% | Processing of non-ferrous metals such as copper and cast iron |

| Inert extreme pressure type N2 pole (No. 1 to 4) |

can be | Less than 2 at 150°C | 30~95% | General cutting processes |

|

Inert extreme pressure type |

can be (including sulfur) |

2 or less at 100°C 2 or more at 150°C |

30~95% | General cutting processes Heavy cutting Cutting difficult-to-cut materials |

| Active extreme pressure type N4 pole (No. 1 to No. 8) |

can be (including sulfur) |

3 or more at 100°C | 30~95% | Heavy cutting Cutting difficult-to-cut materials |

Furthermore, "N1" to "N4" are further subdivided according to sulfur content, fatty oil content, and kinematic viscosity, with "N1" and "N2" classified as Nos. 1 to 4, and "N3" and "N4" classified as Nos. 1 to 8.

(3) Characteristics and classification of water-soluble cutting oil

Mixing "water and oil" with surfactants

Water-soluble cutting fluids use surfactants to combine and mix water and oil, which do not normally mix.

An "interface" is the boundary surface formed between the surfaces of two substances with different properties, and an interface also exists between water and oil.

A "surfactant" is a substance that acts on this "interface" to change its properties. The JIS standard defines it as "a synthetic substance that emulsifies water-insoluble liquids, disperses powders and solids in water, and cleans stains from fibers and metals." For example, familiar products such as soap and detergent contain surfactants.

JIS classification and general classification

Water-soluble oils are classified as "A1" to "A3" based on appearance when diluted and the solubility of the ingredients in water. However, they are generally classified into the following common names: "emulsion type," "microemulsion type," "soluble type," and "chemical solution type."

Even if the oily substances are mixed evenly with the surfactant, if the oily substances are large, the liquid will become cloudy and is called an emulsion type. Conversely, if the oily substances are small and light can pass through them, the liquid will become transparent and is called a soluble type.

| JIS classification | Nickname | appearance | Features |

|---|---|---|---|

| A1 type (No. 1 and 2) |

Emulsion type | milky white | High lubricity and effective for low-speed heavy cutting. It also has little effect on paint and rough hands. |

| Microemulsion type | milky white (slightly transparent) |

||

| A2 type (No. 1 and 2) |

Soluble type | transparent translucent (May be colored) |

High penetration and effective for high speed light cutting. The type has a big impact on the paint. |

| A3 type (No. 1 and 2) |

Chemical solution type | transparent (May be colored) |

Excellent rust resistance and little decay. Depending on the type, the impact on paint and rough hands may be somewhat large. |

Previous item: 1-2. Cutting fluids and their effects

Next item: 1-4.How to choose cutting fluid

People who viewed this page also checked out these documents:

Inquiry

For product inquiries, quote requests, etc.

Please feel free to contact us.